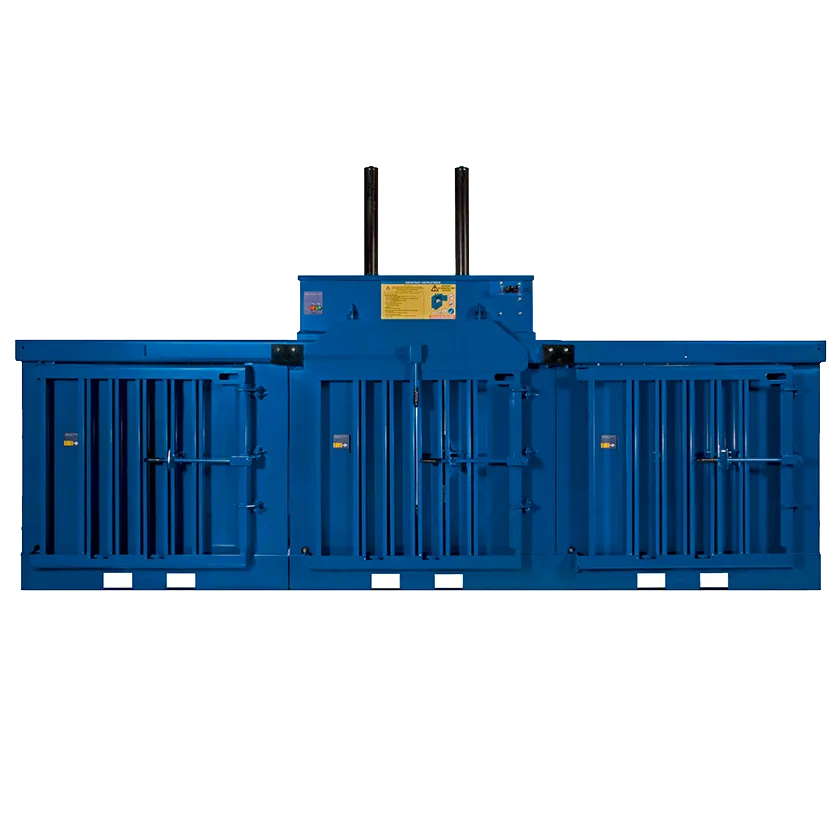

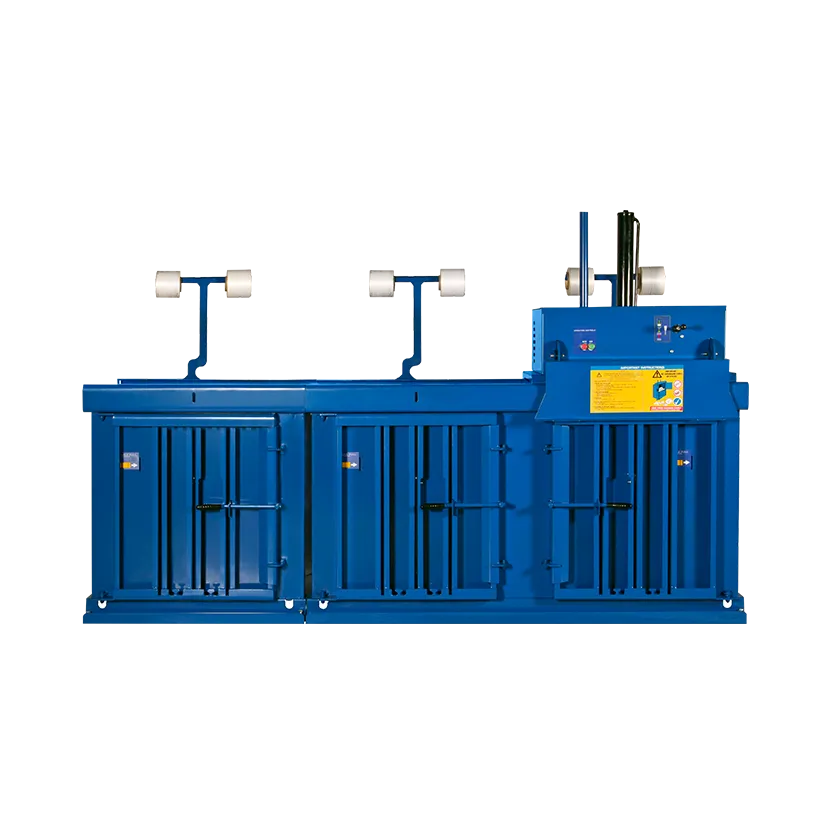

LFA 151

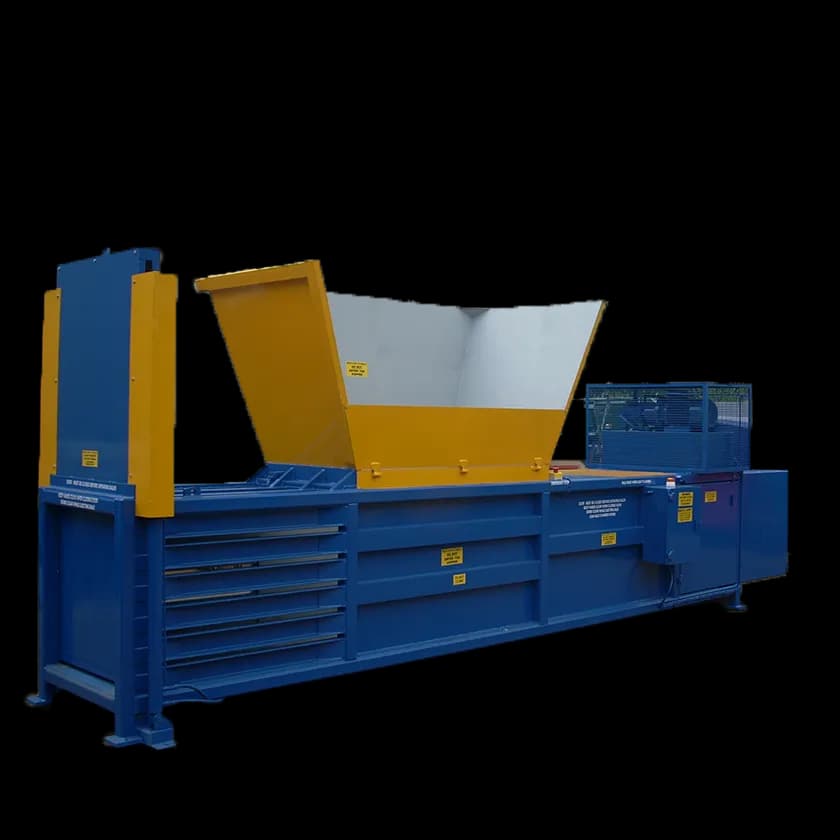

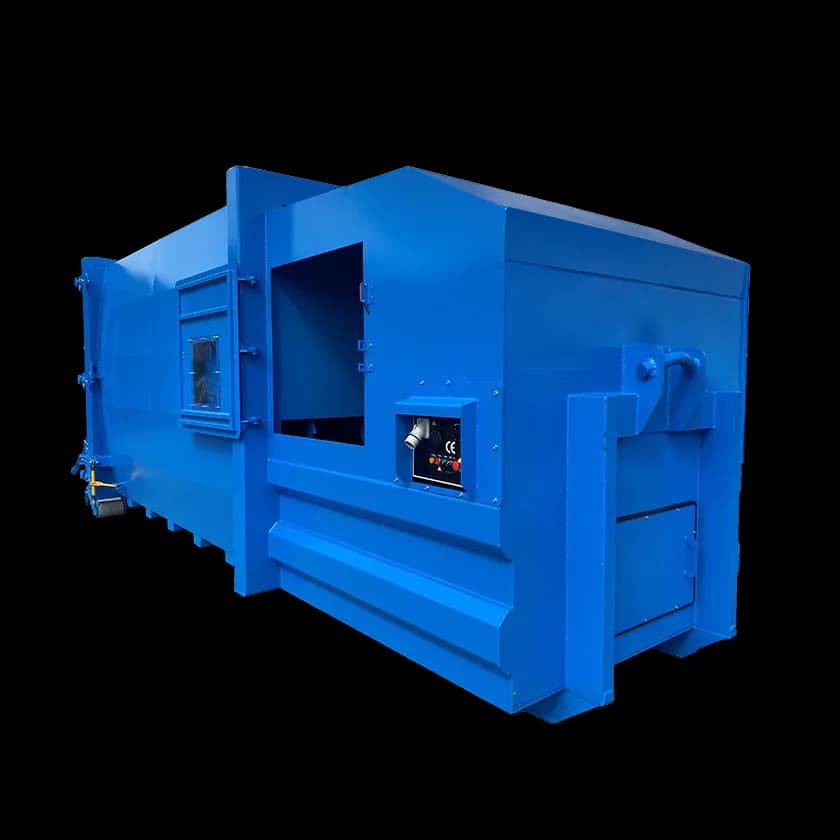

The LFA 151 is our most popular mid range vertical baler. It is one of our seasoned veterans that has been in our range for 20+ years. It is an ideal machine for small/medium quantities and size of material due to its 1090 x 540mm feed opening and 10t compaction force. With a fast cycle speed of 55 seconds, it will quickly bale up material.

The LFA 151 creates bales up to 180kg (depending on material) and has an auto eject feature making bale ejection easy. With an IP rating of 65, it can withstand all forms of weather so it can be sited inside or outside. The most common types of materials baled are cardboard, plastic film, dry waste and paper, but it can also bale other materials.

Suitable For

Cardboard

Cardboard Fabric

Fabric Flexible Metals

Flexible Metals Flexible Plastic

Flexible Plastic Paper

PaperBale Weights

- Cardboard

- ~150kg

- Plastic

- ~180kg

Product Variations

Arrange a Callback with an Expert

We can help you pick the right machine to save your business money on waste disposal.

Compare with Similar Machines

This Machine | Larger | |

|---|---|---|

| Price | From £24 P/W | From £15 P/W |

| Throughput | Medium | Low |

| Suitable For |  Cardboard Cardboard Fabric Fabric Flexible Metals Flexible Metals Flexible Plastic Flexible Plastic Paper Paper |  Cardboard Cardboard Fabric Fabric Flexible Metals Flexible Metals Flexible Plastic Flexible Plastic Paper Paper |

| Bale Size |

|

|

| Machine Size |

|

|

| Feed Opening |

|

|

| Bale Weight |

|

|

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.