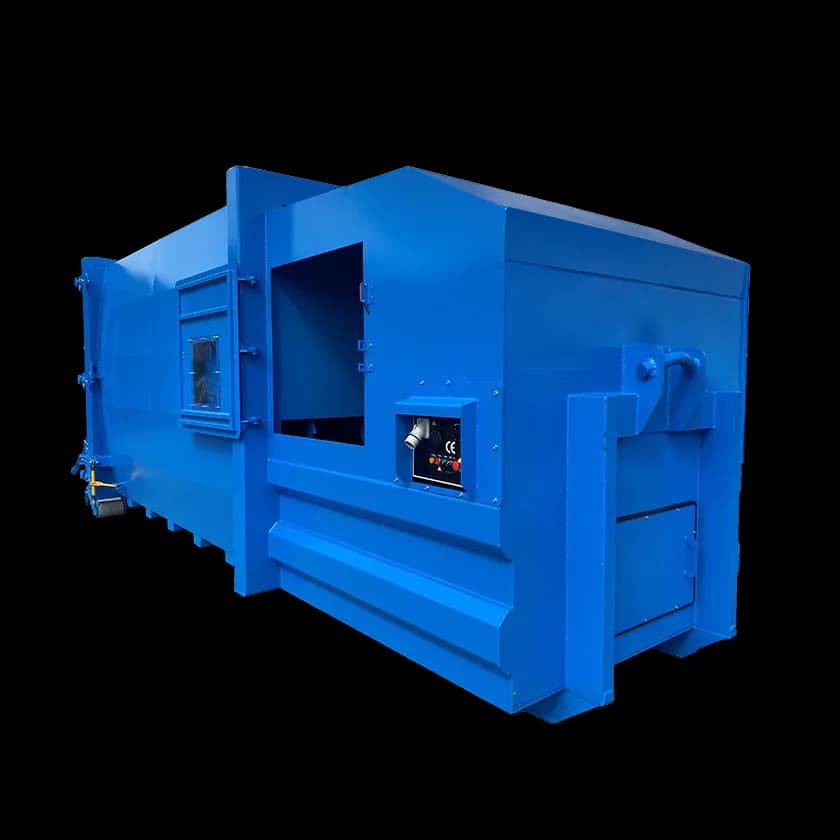

Portable Compactors

Portable compactors are used where general or residual waste needs to be compacted and removed as a single sealed unit. Unlike static compactors, the compactor and container are collected and replaced in full, rather than remaining fixed on site. They’re commonly used where space is limited or waste needs to stay enclosed until collection. Smaller units are typically chain-lift, while larger portable compactors use hook-lift systems to suit higher waste volumes and site access. Portable compactors are widely used on commercial and industrial sites handling general waste, particularly where bins or skips overflow, odour becomes an issue, or collection costs start to rise. By keeping waste sealed and removing it in full, they help sites keep waste areas tidy without installing permanent equipment.

Get Expert AdviceArrange a Callback with an Expert

Talk to our team about how a portable compactor can streamline your waste handling, reduce disposal costs, and enhance on-site efficiency.

Common Problems Portable Compactors Help Solve

Portable compactors are frequently introduced to address practical issues such as:

- Bins overflowing before scheduled collections

- Too many skip or bin lifts increasing costs

- Loose waste blowing around yards or service areas

- Hygiene concerns near food, retail or public-facing areas

- Limited space for multiple bins or large skips

By compacting waste into a single sealed unit, sites can keep waste contained, reduce manual handling and simplify how waste is managed day to day.

Portable Compactors vs Static Compactors

Sites choosing between a portable compactor and a static compactor are usually deciding how waste should be stored and removed.

Portable compactors keep waste sealed inside the unit and are removed in full, making them well suited to sites where space, hygiene or containment are priorities. Static compactors remain fixed in place and compact waste into a separate RoRo container.

Both systems are used widely across UK sites, and the right choice depends on how waste is produced, handled and collected day to day.

In most cases, a portable compactor is used for general waste, with a baler handling recyclable materials such as cardboard or plastic. This allows general waste to be kept under control, while recyclable material is dealt with separately.

How Portable Compactors Are Used Day to Day

Portable compactors are used where loose bins or skips aren’t practical and waste needs to be removed in a sealed unit.

Instead of emptying bins or exchanging separate containers, the entire unit is collected, emptied and returned once it reaches capacity. This keeps waste contained throughout the process

Because the unit is removed as a whole, portable compactors work well on sites where fixing equipment to hardstanding isn’t suitable.

Collection is usually arranged on an ad hoc basis, with the full unit emptied once it approaches capacity rather than on a fixed weekly schedule.

Chain-lift vs Hook-lift Portable Compactors

Chain-lift units are generally smaller and suit sites with limited space or lower waste output, while hook-lift compactors are designed for higher volumes.

Most waste hauliers operate both chain-lift and hook-lift vehicles, so the choice is usually driven by waste volume, site access and available space rather than vehicle availability.

Where Portable Compactors Make Sense

Portable compactors are typically chosen where waste needs to remain enclosed and handled with minimal manual intervention. They’re most often used for general and residual waste, but are also well suited to food waste, non-recyclable packaging and contaminated recyclables where hygiene and containment are important.

On many sites, portable compactors replace loose bins or open skips that regularly overflow, attract pests or create housekeeping issues. Keeping waste contained within a sealed unit helps maintain cleaner yards and service areas, particularly on busy or shared sites or where waste is close to public access.

Portable compactors are commonly used alongside waste balers, with the compactor handling residual or food waste and the baler used for clean cardboard and plastic recycling. Where recyclable material is produced in volume, balers remain the more appropriate solution.

Food waste can be handled very effectively using a portable compactor, provided the correct wet-spec machine is selected. This typically includes features such as reinforced construction, sealed doors and a pendulum ram design to cope with heavier, wetter waste without leakage or excessive wear.

Portable compactors aren’t suitable for every application. Very heavy single items, highly abrasive materials or continuous high-speed production waste may require alternative equipment. In those cases, other compaction or recycling systems are usually a better fit.

Typical Installations

Portable compactors are installed across a wide range of industries, including:

- Warehousing and logistics operations

- Manufacturing and production facilities

- Retail back-of-house and distribution sites

- Food production and food processing environments

- Printing and packaging sites

- Healthcare and pharmaceutical facilities

- Industrial service and engineering sites

- Hospitality, leisure and public-sector facilities where waste needs to remain enclosed between collections

They’re particularly effective where waste is generated steadily throughout the day and needs to be controlled as part of normal operations, rather than collected from multiple bins.

Choosing the Right Portable Compactor

There isn’t a single portable compactor that suits every site.

In practice, the right setup usually comes down to what the waste actually is, how quickly it builds up during the day, how it’s loaded, and how easy it is for the collection vehicle to access the unit. Space constraints often dictate whether a smaller chain-lift compactor or a larger hook-lift unit is more suitable, and power availability also needs to be considered early on.

On most sites, portable compactors aren’t collected to a fixed timetable. Instead, the unit is collected when it’s getting close to full, which keeps collections flexible and avoids unnecessary lifts.

Collection arrangements are typically agreed with the site’s waste contractor, with the full unit taken away, emptied and returned when required. This keeps collections flexible and avoids unnecessary vehicle movements.

Units can be supplied from stock, refurbished inventory or built to order, allowing sites to balance lead time, budget and operational requirements.

Hire or Purchase?

Some sites choose to hire a portable compactor where capital spend needs to be controlled or waste volumes are still being assessed. Others prefer to purchase once waste output is established and the unit will form part of a long-term setup.

Once we understand how waste is handled on site, we can advise on which route is likely to make the most sense.

Refurbished portable compactors are also available, offering a cost-effective option where budgets or lead times are a consideration. These units are checked, serviced and prepared for continued commercial use before supply.

Portable Compactors Supplied Across the UK

We supply portable compactors to businesses across the UK and regularly support sites using static compactors, waste balers and bin tippers as part of wider waste handling systems.

On larger or more complex sites, portable compactors are often part of a broader setup that may also include vertical balers or horizontal balers for recyclables, or jumbo roll packers where wood waste is produced.

Portable compactors can also be supported with servicing, refurbishment and ongoing maintenance where required, helping keep waste handling consistent and predictable.

Once installed, portable compactors are integrated into existing waste collection arrangements, with operators shown how to use the unit correctly and collections continuing as normal through full unit exchanges.

If you’re reviewing how general waste is managed on site and want to understand whether a portable compactor would be a practical fit, speak to our team and we’ll talk it through based on how waste is actually produced and handled day to day.

Portable Compactor FAQs

Arrange a Free On-Site Audit Today

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.