In-bin, in-bag and in-skip compactors

In-bin, in-bag and in-skip compactors are typically used where waste volumes don’t justify installing a full static or portable compactor, but loose bins, bags or skips are becoming difficult to manage. They reduce waste volume at the point it’s produced, helping cut down collections, improve housekeeping and keep waste contained without the need for larger powered or fixed compaction systems. These compactors are commonly used inside buildings, in service corridors, loading bays and waste rooms where space is limited and waste needs to be handled as part of normal day-to-day operations. Depending on how waste is managed on site, they may also be referred to as bin compactors, wheelie bin compactors, bag presses, waste bag compactors or skip compactors. This category includes compactors designed for use with 240 and 1100 litre wheelie bins, in-bag compactors and bag presses, rotary systems such as Bergmann roto compactors, and block compactors used with skips. Each option suits a different waste volume, layout and handling requirement, allowing sites to reduce waste efficiently without stepping up to larger compaction equipment.

Get Expert HelpArrange a Callback with an Expert

Find out how much you could save by compacting your waste instead of paying to throw it away.

In-Bin Compactors (Wheelie Bin Compactors)

In-bin compactors are designed to compact waste directly into standard wheelie bins, most commonly 240 litre and 1100 litre wheelie bins.

They’re used where waste is already handled in bins, but collections are becoming too frequent or bins are overflowing before scheduled lifts. By compacting waste inside the bin, sites can significantly increase capacity without changing existing collection contracts or bin infrastructure.

In-bin compactors are commonly used in:

- Retail back-of-house areas

- Hospitality and leisure sites

- Healthcare and public buildings

- Manufacturing and light industrial environments

They’re particularly useful where space is limited and bins need to remain mobile.

In-bin compactors are powered systems, offering consistent compaction with minimal manual handling.

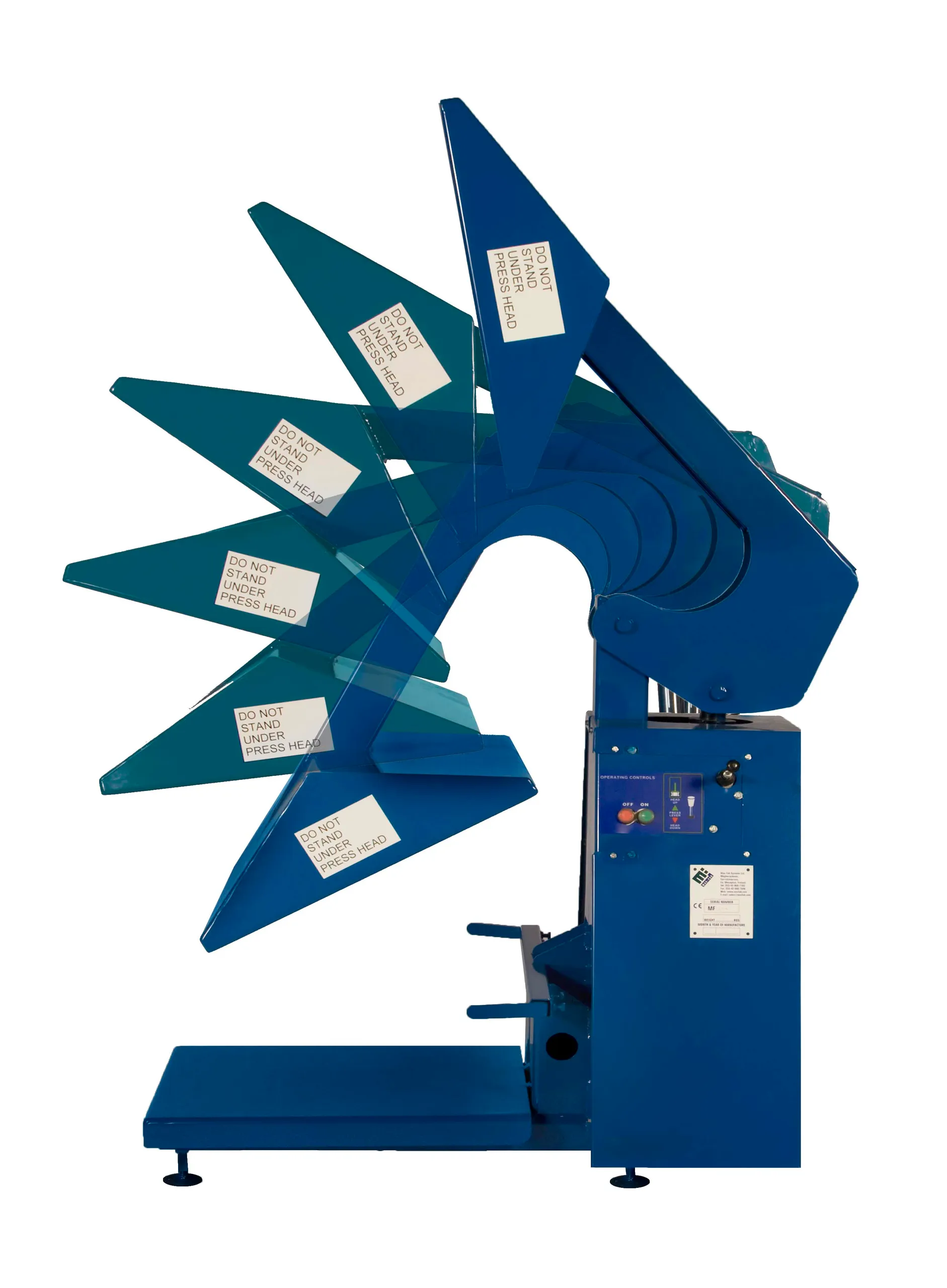

In-Bag Compactors (Bag Presses & Roto Compactors)

In-bag compactors compress waste directly into heavy-duty bags rather than bins or skips. This includes traditional bag presses as well as rotary systems such as the Bergmann roto compactor, which compacts waste by rotating it within the chamber.

These machines are typically chosen where:

- Ceiling height or floor space is restricted

- Waste volumes are steady but relatively low

- Waste needs to remain contained in bags

In-bag compactors are often installed in production areas, waste rooms and service corridors where housekeeping and containment are important. Once full, bags are sealed and removed for disposal, avoiding loose waste handling.

Common applications include general waste, packaging waste and contaminated non-recyclable materials.

Like in-bin compactors, in-bag systems are powered, providing better compaction efficiency and reduced manual labour compared to non-powered alternatives.

In-Skip Compactors (Block Compactors / Forklift Skip Compactors)

In-skip compactors are used where waste needs to be compacted directly into a skip without installing powered equipment or fixed infrastructure.

In this category, waste is compacted using block compactors, often referred to as forklift skip compactors. There’s no power involved - the compaction comes purely from the weight of the block being lowered into the skip.

A block compactor consists of heavy concrete blocks that are lowered into a skip using a forklift. As waste builds up, the block is repeatedly lowered to compress material, increasing the amount that can be loaded into the skip before collection.

Because block compactors rely on weight rather than powered hydraulics:

- They involve more manual handling

- They deliver a lower compaction ratio

- Waste is compacted into an open skip rather than a sealed container so material can spring back

Block compactors are therefore best suited to sites looking for a simple, low-cost way to increase skip capacity, rather than those needing maximum compaction efficiency or enclosed waste storage.

They require:

- No electricity

- No hydraulics

- No fixed installation

Typical environments include:

- Manufacturing and engineering sites

- Packaging and distribution facilities

- Industrial service and workshop environments

Where higher compaction ratios, sealed containment or powered operation are required, in-bin, in-bag, portable or static compactors are usually more appropriate.

For bulky or long materials such as timber offcuts or wood waste, jumbo roll packers are often the more suitable option and are covered separately.

Where These Compactors Make Sense

In-bin, in-bag and in-skip compactors are usually introduced when:

- Bins or bags are filling too quickly

- Collection costs are increasing

- Loose waste is creating housekeeping or safety issues

- Space won’t allow a larger compaction system

They’re frequently used alongside other equipment, such as vertical balers or horizontal balers for cardboard and plastic recycling, allowing general waste to be compacted while recyclable material is handled separately.

Choosing the Right Compactor

There isn’t a single solution that suits every site. The right compactor depends on practical details such as:

- The type of waste being produced

- How quickly it builds up

- Available space and ceiling height

- How waste is currently collected

Some sites start with a bin or bag compactor and move to larger equipment as volumes increase. Others use these machines long-term where waste output is consistent and contained.

These compactors are most often specified by facilities managers, site managers and operations teams who need to reduce waste volume without changing existing contracts or introducing larger powered systems.

Units are available new or refurbished, allowing sites to balance budget, lead time and operational requirements.

Hire or Purchase

Many of these compactors are available to hire or buy, depending on how the site operates.

Hire is often chosen where waste volumes are still being assessed or capital spend needs to be controlled. Purchase is more common where waste output is established and the equipment forms part of a long-term setup.

Refurbished machines are also available and are fully checked and prepared for continued commercial use.

In-Bin, In-Bag & In-Skip Compactors Supplied Across the UK

We supply in-bin, in-bag and in-skip compactors to businesses across England, Scotland and Wales, and regularly support sites using balers, static compactors and portable compactors as part of wider waste handling systems.

Equipment can be supplied with servicing, refurbishment and ongoing support where required, helping keep waste handling predictable and cost-effective.

If you’re reviewing how waste is handled on site and want to understand whether a bin compactor, bag press, roto compactor or forklift block compactor would be the right fit, we can talk it through based on how waste is actually produced and managed day to day.

Arrange a Free On-Site Assessment

Speak with our team about how a bin, bag or block compactor can compact waste efficiently, and save you money.