LFA ACC 4 - Small Aerosol Can Crusher

The LFA ACC 4 aerosol can crusher is designed to safely degas and crush aerosol cans prior to disposal. By removing residual propellant gases, the machine allows aerosol cans to be treated as non-hazardous waste, helping significantly reduce disposal costs compared to untreated aerosols.

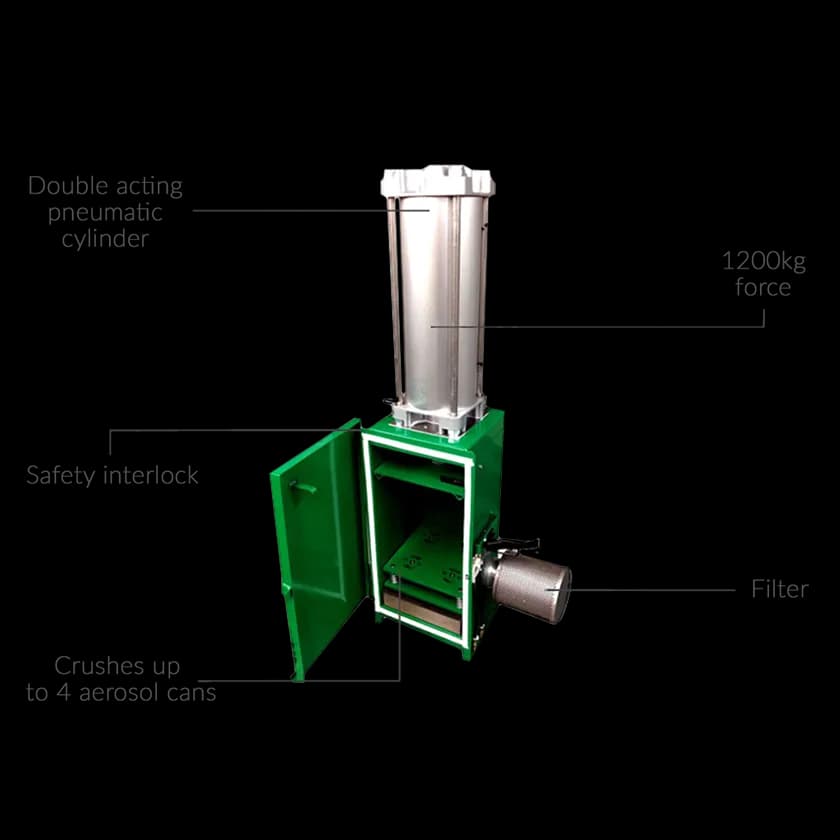

Using a 1.2 tonne compaction force, the LFA ACC 4 crushes aerosol cans by up to 80%. Up to four aerosol cans can be loaded into the crushing chamber at one time, with a maximum can height of 260mm, and other cans can also be processed provided they fit within the chamber.

During operation, gases released from the cans are filtered through an integrated carbon filter. This removes propellants from the cans, addressing the pressurised nature that makes aerosols hazardous prior to treatment. The machine is also fitted with an integrated sump to capture any residual liquids released during the crushing process.

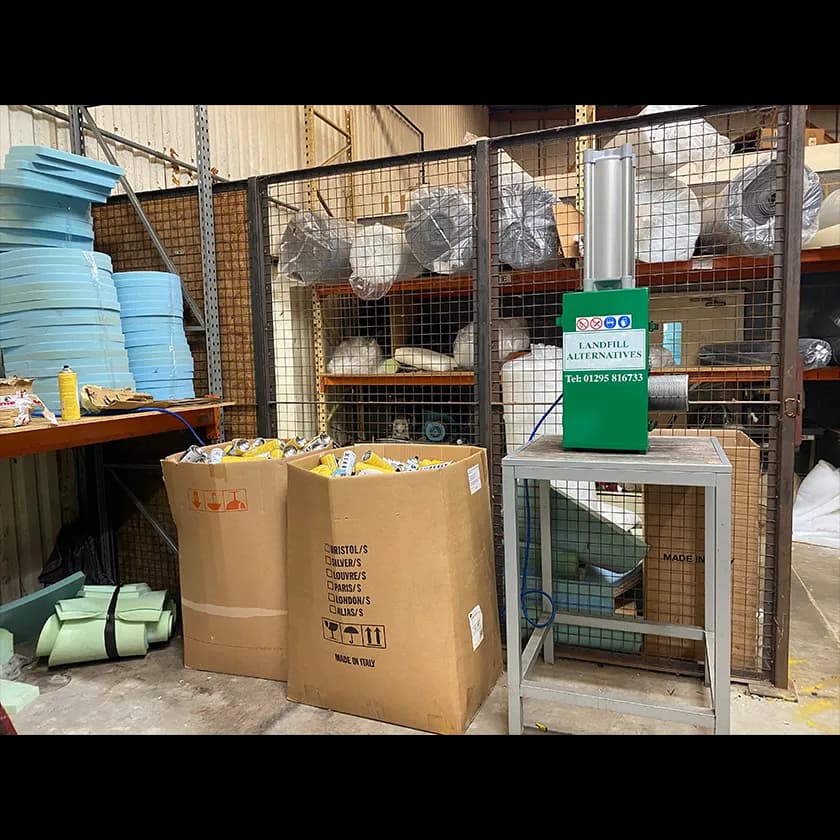

The LFA ACC 4 is commonly used for aerosol paint spray cans, lubricants, cleaners, sprays and coatings generated in workshops, maintenance areas, manufacturing sites and industrial back-of-house locations across the UK.

Aerosol cans should be used and empty before being processed through the machine. Once crushed and degassed, the cans can then be disposed of safely.

The LFA ACC 4 is ATEX rated for the safe degassing of aerosol cans where flammable propellant gases are released during the crushing process.

An air compressor can be supplied if required, allowing the LFA ACC 4 to be installed on sites where compressed air is not already available.

Available new to purchase or lease.

Suitable For

Aerosol

Aerosol

Arrange a Callback with an Expert

We can help you pick the right machine to save your business money on waste disposal.

Compare with Similar Machines

This Machine | Larger | |

|---|---|---|

| Price | From £13 P/W | From £22 P/W |

| Throughput | Medium | High |

| Suitable For |  Aerosol Aerosol |  Aerosol Aerosol |

| Machine Size |

|

|

| Feed Opening |

|

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.