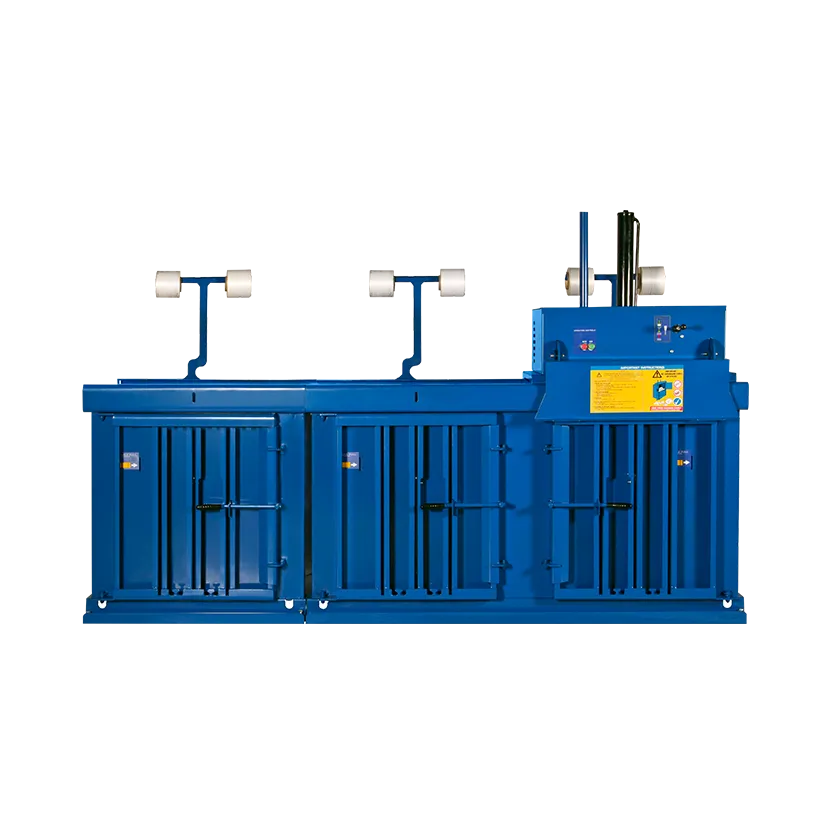

LFA 51 D - Small Double Chamber Baler

The LFA 51 D Double Chamber baler is our smallest multi chamber baler and creates bales up to 75kg in weight. It is an ideal machine for two recyclable waste streams, as having two chambers means that when one chamber is running a compaction cycle, material can be loaded into the other chamber. This eliminates the need to store materials to one side, as you would with a single chamber baler.

A double chamber baler is ideal where different recyclable materials are generated nearby, such as goods in areas where cardboard boxes and pallet wrap are removed. This reduces handling time and avoids cross contamination of materials. Once the bales are produced, your recycler can collect them, helping to reduce wheelie bin and skip costs.

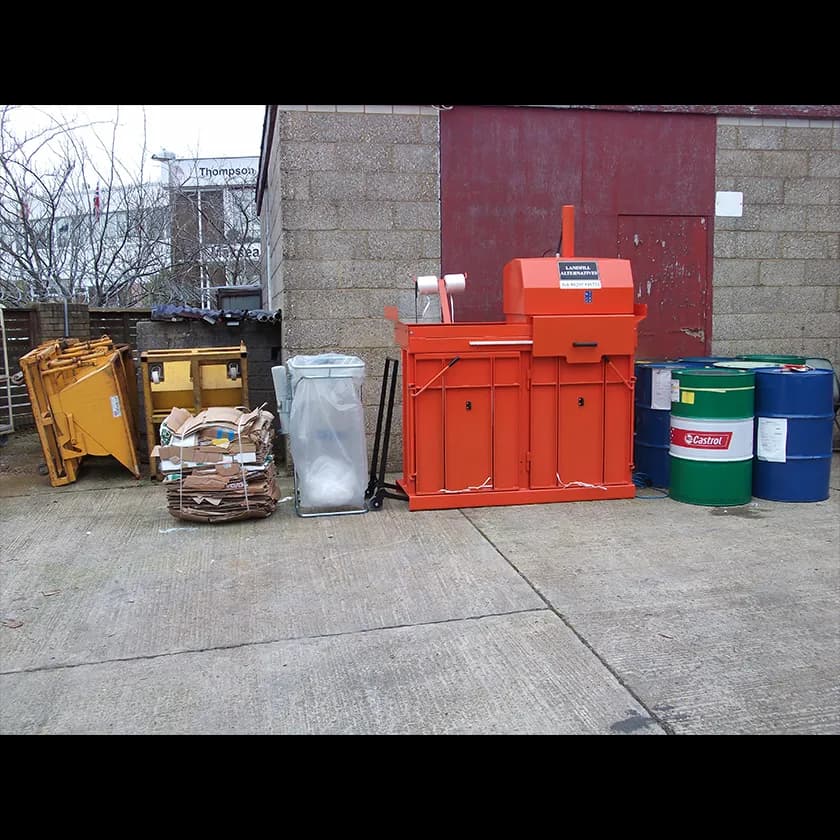

The LFA 51 D is best suited to sites with small quantities and sizes of material due to its two 700 x 500mm top feeding openings. With a fast cycle speed of 35 seconds, it quickly produces a bale. With an IP65 rating, the machine can be sited inside or outside. As the bales are compact at only 700 x 675 x 500mm, a bale trolley is supplied to eject the bale, making bale ejection simple and easy to use.

The most common types of materials baled are cardboard, plastic film and paper, though it can also bale other materials. Common industries include warehousing, fulfilment centres and production environments across the UK.

Available new or refurbished, to purchase or lease.

Suitable For

Cardboard

Cardboard Flexible Plastic

Flexible Plastic Paper

PaperBale Weights

- Cardboard

- ~75kg

- Plastic

- ~75kg

Arrange a Callback with an Expert

We can help you pick the right machine to save your business money on waste disposal.

Compare with Similar Machines

This Machine | Smaller | Larger | |

|---|---|---|---|

| Price | From £21 P/W | From £15 P/W | From £40 P/W |

| Throughput | Low | Low | Low |

| Suitable For |  Cardboard Cardboard Flexible Plastic Flexible Plastic Paper Paper |  Cardboard Cardboard Fabric Fabric Flexible Metals Flexible Metals Flexible Plastic Flexible Plastic Paper Paper |  Cardboard Cardboard Flexible Plastic Flexible Plastic Paper Paper |

| Bale Size |

|

|

|

| Machine Size |

|

|

|

| Feed Opening |

|

|

|

| Bale Weight |

|

|

|

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.