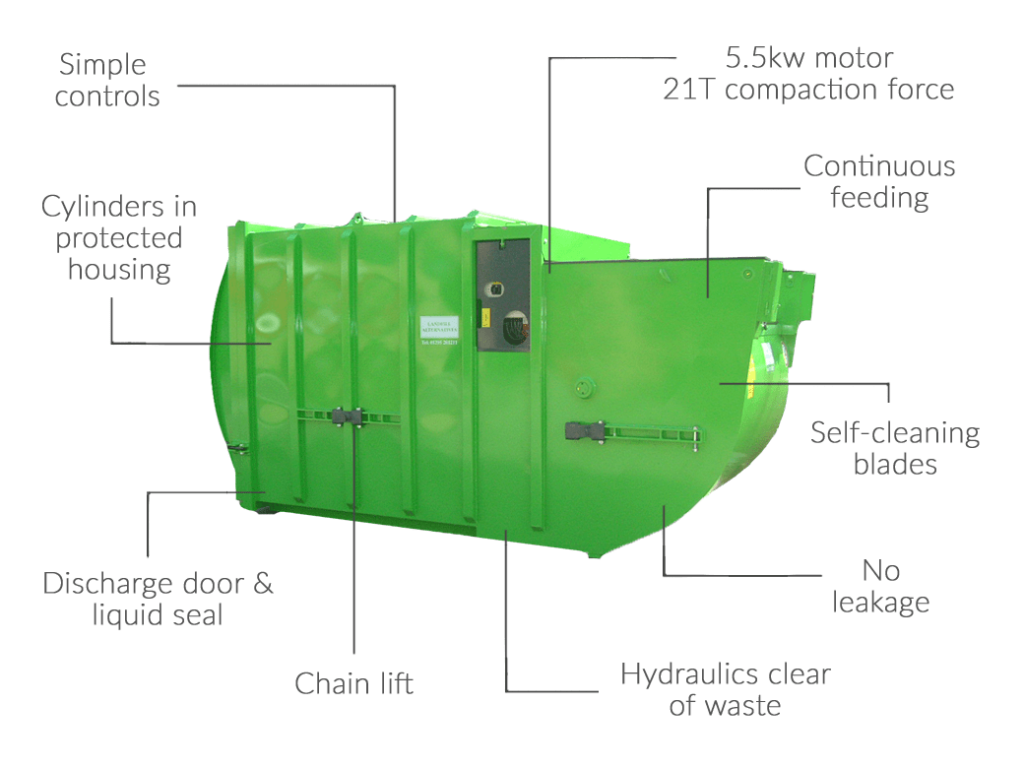

MPB 10 – Portable Compactor

The MPB 10 is our 10m³ chain lift, portable compactor. The main purpose of a portable compactor is to fully contain all waste whilst reducing the amount of transport required to dispose of the waste. By using the MPB 10, it is ensured that charges are correct for disposal instead of being overcharged for under capacity skips and bins. The powerful 21t compaction force can achieve payloads of up to 4t of general waste but in some instances, up to 7t. As waste is unsightly and most often, smelly, one of the major benefits of a portable compactor is that everything thrown into the machine is compacted into the fully sealed, watertight chamber which means there is no leakage of waste, residuals and smells unlike conventional bins/skips which often leak leading to vermin problems and other negative impacts.

The MPB10 has a small 1985x4500mm footprint so it is ideal for tight areas taking up about the space of a car park bay. It also uses a very fast pendulum compaction mechanism which has a self-cleaning scraper blade, these features mean it can be continually fed and there is no requirement for cleaning out wet, grotty inspection houses. Boasting a large feed opening of 1400x1000mm, it is ideal for bulky waste and allows various feeding methods such as hand loading, forklifts, tipping skips etc.

Product Details

| Product Dimensions | |

|---|---|

| Overall Width | 1985mm |

| Overall Height | 2330mm |

| Overall Weight | ~2750kg |

| Feed Opening Width | 1400mm |

| Feed Opening Depth | 1000mm |

| Length | 4500mm |

| Technical Specification | |

|---|---|

| Compaction Force | 21T |

| Motor | 5.5kW |

| Cycle Time | 35 Seconds |

| Capacity | 9.6m³ |

| Compaction Mechanism | Pendulum |

| Lifting Method | Chain Lift |

| Electricity Supply | 3 phase, 415V, 32A |

The compactor can be specified with a hand feed door or a bin lift attached to tip 500-1100ltr wheelie bins for better manual handling (MPB 10 BL). For further customisation, contact us and we will try to meet all requirements.

Typically, the minimum amount of waste per week to gain a cost saving would be either:

- 1100ltr wheelie bins – Ten GW (General waste)

- FEL (Front end loader) skip(s) – Two GW

- REL (Rear end loader) skip(s) – One GW

Features

- E-stops

- Twin cylinders

- ¾ full indicator

- Automatic cycle

- Large feed opening

- Self-cleaning scraper blade

- Pendulum compaction method

- Simple, easy to operate controls

- Hydraulic pack separate from waste

- Powerful 21 tonne compaction force

- Top hinged rear door with 100% all round seal

- Rated IP65 so safe to be sited inside or outside

- Lockable front hinged feed door & control panel

- Rollover rear door to achieve maximum tonnages

- Tapered sides to the container for easy emptying

Benefits

- Helps prevent fly tipping

- Reduces waste disposal costs

- Reduces contractor traffic on site

- More environmentally friendly

- Saves on labour from reduced material handling

- No longer being charged for air voids in skips/bins

- Reduces carbon footprint and complies with ISO 14001

- Reduces the amount of space on site taken up by bins and skips

- Keeps the yard much tidier – contains all waste, liquids and bad smells

The MPB 10 is extremely easy to use and requires very little manual work.

Step 1 – Feeding

This step is straight forward – throw the waste into the charge box and press the green ‘go’ button to start the compaction cycle. The pendulum blade will sweep up all the waste and compact it into the back container. This cycle will run 3 times but can be configured to run more/less or on a timer.

Step 2 – When is the compactor full?

The compactor has an indicator to notify the operator when it is ¾ full. Once this illuminates, the operator can calculate when the compactor will be full and when it needs to be collected by the waste contractor.

Step 3 – Waste removal

The contractor will arrive on site with a chain lift vehicle and will unplug the MPB 10. Four chains are attached to the connection points located on all four corners of the compactor. The vehicle will lift the compactor up and sit it on the vehicle bed. The compactor will be taken away, emptied and returned ready to start using again.

As simple as that! It probably takes longer to read the operation than to implement it. As part of the package, one of our trusty engineers will come to site and show the team how to operate it in person. Training certification can be supplied if required.

*Note – Refurbished models may vary in operation slightly, but the principle will remain very similar.

MPB 10 – Portable Compactor Brochure

Interested in learning more about the MPB 10 – Portable Compactor? Leave your details below to get an instant free copy of our brochure.

Benefits of Compacting

-

To reduce waste disposal costs

-

To keep the yard much tidier – no mess or leakage

-

To gain a rebate of recyclable material

-

To prevent fly tipping

-

To have less contractor traffic on site

-

To be more environmentally friendly

More Questions Than Answers?

We appreciate that our comprehensive range of machinery can sometimes make it difficult to find the right machine to suit your requirements.

Our Product Finder tool makes it easy to find the perfect Baler, Crusher or Compactor to satisfy your business requirements.

Show MeRequest a callback

Prefer to speak to us in person? Then leave your details below and a member of the team will be in touch shortly.