Benefits of Mill Sized Balers

Are you looking to recycle large quantities of cardboard, plastic film, dry-waste, and rigid plastic on a regular basis and require a heavy-duty and robust machine? Then a Mill Size Baler is the ideal solution. Our Mill Size Balers are capable of processing high volumes of waste into extremely dense, mill size bales, up to ~500kg that can be sent directly to the recycling mill. This removes the requirement for any additional processing and ensures you receive maximum rebate on your material. With smaller footprints, Mill Size Balers are the perfect option for businesses that need an effective and straightforward solution to effectively process large volumes of cardboard, plastic and other materials when a Horizontal Baler is not suitable.

Difference between Mill Size Balers & Vertical Balers

Despite the underlying concept and benefits being identical, apart from processing capability, there is one other key factor that differentiates a Mill Size Baler to a smaller model; Bale size. The combination of a large chamber and high levels of compaction force applied enable them to produce extremely dense, uniform, bales that weigh ~500kg. These are known as Mill Size Bales and due to their uniformity and density are more efficient to transport.

Although smaller Vertical Balers also produce bales, their size and weight are less consistent. As a result, it would be inefficient to transport these to recycling centers, which are typically overseas. Therefore, small bales are broken down and re-baled into mill size bales before being sent to the recycling plant. The additional processing required reduces the value and subsequently, lower levels of rebate are achieved.

Consequently, if your business has sufficient waste volumes, having a Mill Sized Baler can bring revenue to your business, as well as being an efficient way to satisfy your waste disposal requirements. The rebate received for mill size bales would typically be over £70 per ton depending on the material and quantity stored.

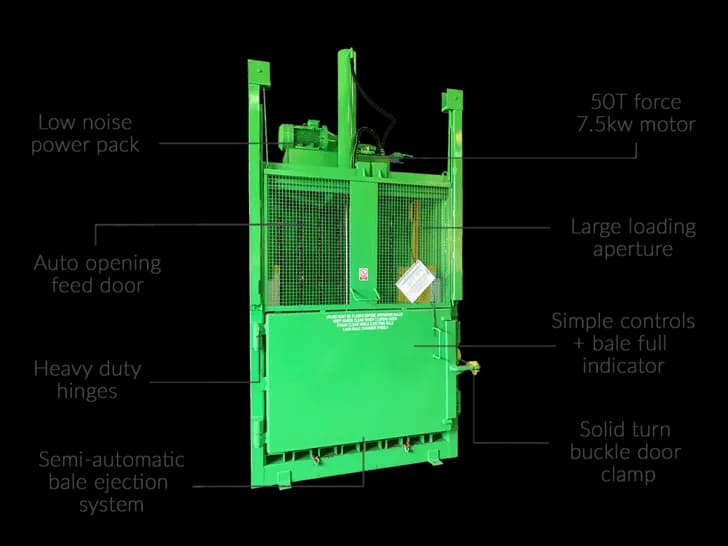

Landfill Alternatives offer two models of Mill Size Vertical Balers for sale and lease hire; the LFA 500 and LFA 500HD.

Suitable For

The LFA 500 and 500HD are capable of processing incredibly high volumes of a wide array of recyclable materials including:

Cardboard

This machine is perfect for recycling cardboard; the large feed door ensures it doesn’t need to be flattened first.

Plastic Film

With 50T of compaction force, our Mill Size Balers can produce high-density plastic bales up to ~650kg.

Dry Waste

These machines are capable of handling dry-waste such as fabric and flexible metals.

Paper

Provided the paper is whole or strip shredded then it can be baled and recycled, in some circumstances, confetti shredded paper cannot be processed.

Rigid Plastic

Due to its re-enforced hinges and solid metal frame, the LFA 500 Heavy Duty model can handle rigid plastics.

If you’re not sure which machine is suitable for your material, try out our ‘Waste Configurator’ or arrange a free on-site audit.

Benefits

Footprint

Mill Size Vertical Balers enable you to process large quantities of recyclable material in a relatively small footprint in comparison to larger, Horizontal Balers. This makes them the perfect solution when space is restricted or a Horizontal Baler is not suitable.

Easy of use

These machines are straightforward to install and operate. The LFA 500 HD has an automatic door, wide feed aperture, indicator light, and semi-auto bale eject feature. In addition, all these features their superior build quality ensures minimal maintenance, downtime, and noise disruption.

Quick cycle time

With a cycle time of only 32 seconds, it is one of the fastest Balers available on the market. This enables you to process large quantities of recyclables quickly, with minimal labor. The automatic feed door on the HD model also improves efficiency and reduces handling time.

Bale Size

With 50T of compaction force coupled with a large chamber, these machines are capable of producing extremely dense 500kg, mill size bales that achieve maximum rebate.

Automatic Ejection

Once the bale is ready the operator can automatically eject it simply by pressing two buttons. This minimises handling streamlining the entire process.

Considerations

Throughput

Despite being capable of processing large volumes of waste if space permits it may become more efficient to invest in a horizontal baler, which offer a far superior throughput as a result of continuous loading.

Labor Requirements

Vertical Balers can only be loaded by hand, which can tie up your labor force. In contrast, horizontal balers can be fed either by hand, bin tipper, forklift or via a conveyor belt system into a hopper.

To learn more about the differences between Vertical & Horizontal Balers read our article or speak to one of our friendly advisors on 01295 816 733

Case Studies

Our mill size balers are ideal for larger businesses and any industry with large quantities of cardboard and plastic waste such as supermarkets, wholesalers, shopping centres, manufacturing, and logistics centres. Don’t just take our word for it; explore some of our glowing customer testimonials and case studies below.

Conclusion

If your business is considering a robust and heavy-duty Vertical Baler then the LFA 500 range is the perfect option for your business. Take the next steps today by requesting a callback, or fill out this form to arrange a free-onsite audit.