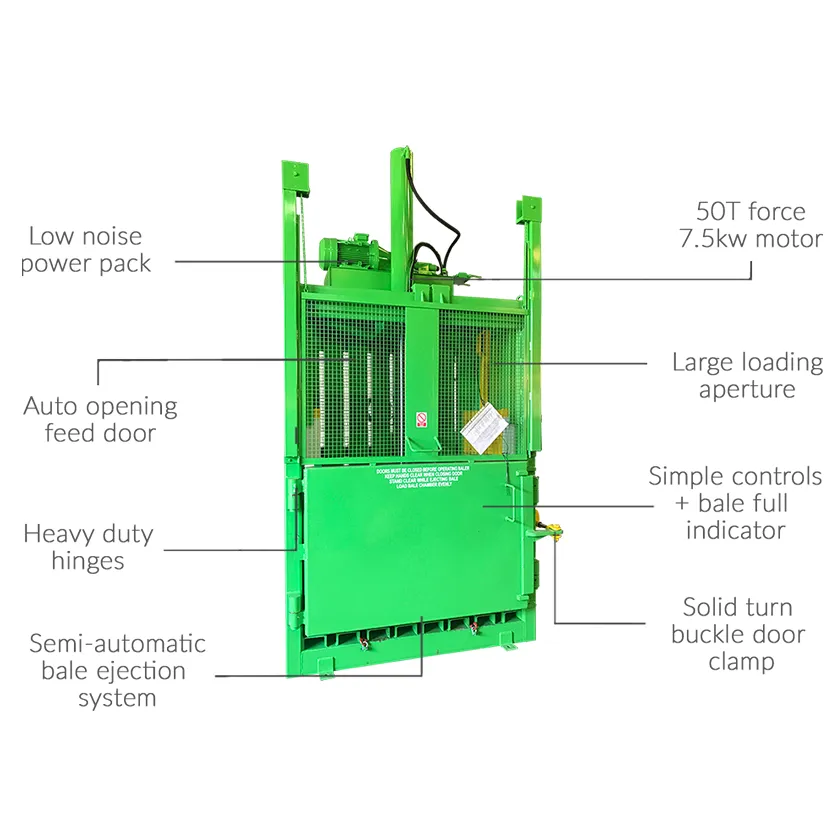

LFA 500 HD

The LFA 500 HD is our largest extra wide, extra fast vertical mill size baler, producing wire tied bales of up to 650kg (depending on material). Built with reinforced hinges and a thicker steel frame, it is especially effective on tougher, springier materials such as rigid plastics. At the same time, it delivers exceptionally dense bales of cardboard, plastic film and paper.

One of the reasons the LFA 500 HD sets itself apart from other mill size balers on the market is its feeding speed. A rapid 32 second cycle time combined with an automatic shutter door means the baler is ready to load again immediately after each cycle - no doors to open, allowing material to be fed straight in, reducing labour waiting time.

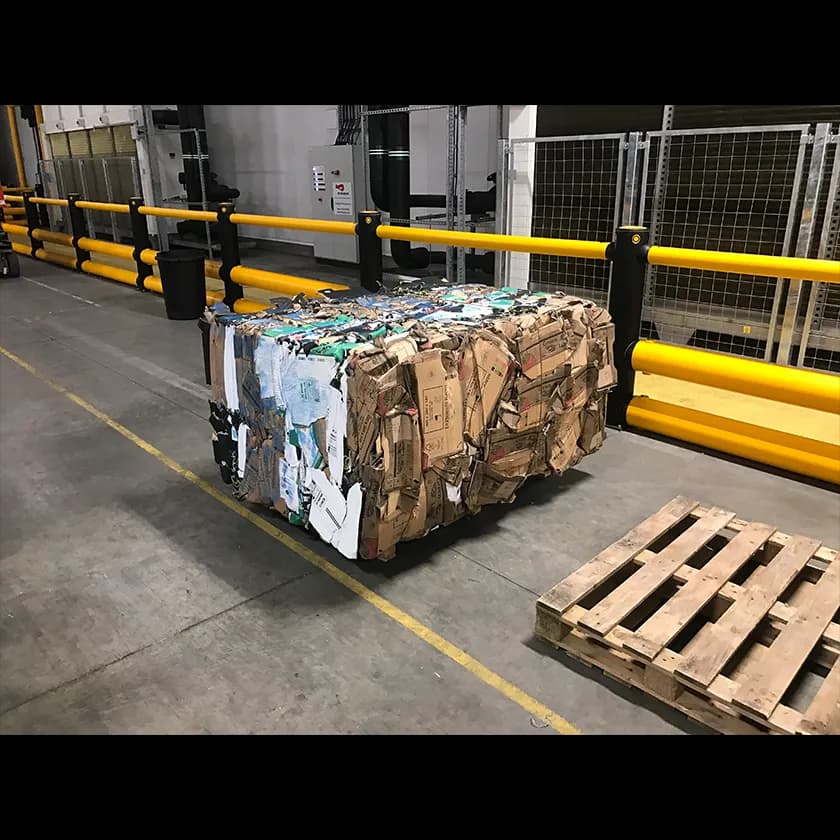

With an extra wide 1560 x 690mm feed opening and 50 tonnes of compaction force, the machine is designed for large volumes of recyclable waste. To gain the best rebate on your recyclable material, recyclers require mill size bales, which the LFA 500 HD produces. Bale ejection is simple thanks to the auto eject system, while an IP65 rating ensures it can be used indoors or outdoors in any weather.

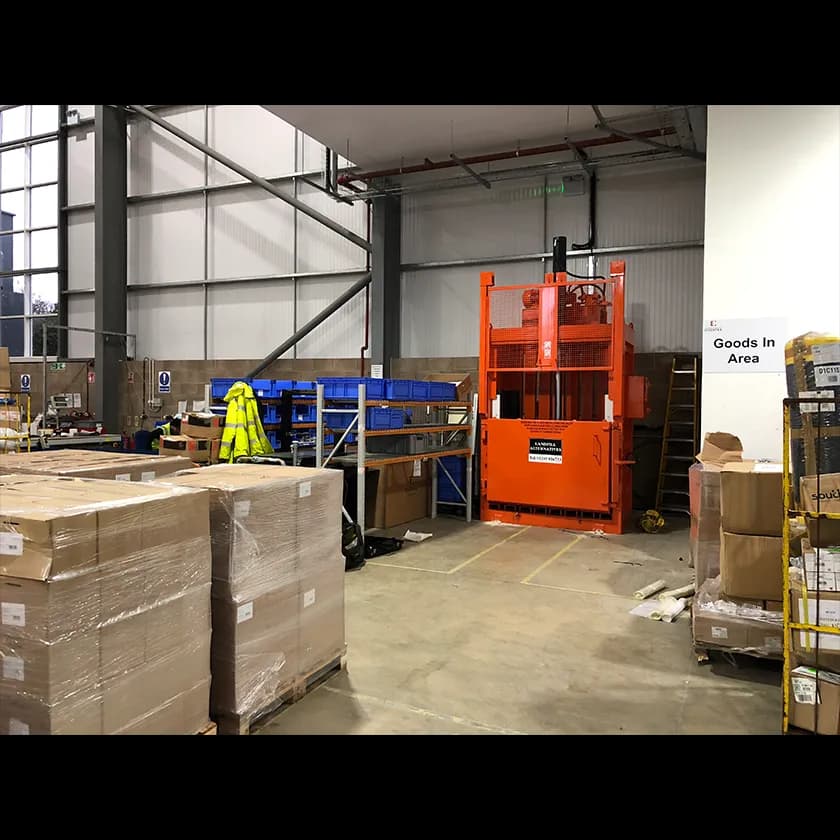

The LFA 500 HD is supplied across the UK to industries such as manufacturing, food production, logistics, recycling, warehousing and fulfilment centres. It is particularly suited to sites producing large volumes of recyclable waste where mill size bales are required by recyclers.

This performance, paired with its extra wide, robust build, makes it the flagship of our vertical mill size baler range.

Available new or refurbished, to purchase or lease.

Suitable For

Cardboard

Cardboard Fabric

Fabric Flexible Metals

Flexible Metals Flexible Plastic

Flexible Plastic Paper

Paper Rigid Plastic

Rigid PlasticBale Weights

- Cardboard

- ~500kg

- Plastic

- ~650kg

Arrange a Callback with an Expert

We can help you pick the right machine to save your business money on waste disposal.

Compare with Similar Machines

This Machine | Smaller | Larger | |

|---|---|---|---|

| Price | From £39 P/W | From £39 P/W | From £150 P/W |

| Throughput | High | High | High |

| Suitable For |  Cardboard Cardboard Fabric Fabric Flexible Metals Flexible Metals Flexible Plastic Flexible Plastic Paper Paper Rigid Plastic Rigid Plastic |  Cardboard Cardboard Fabric Fabric Flexible Metals Flexible Metals Flexible Plastic Flexible Plastic Paper Paper Rigid Plastic Rigid Plastic |  Cardboard Cardboard Fabric Fabric Flexible Metals Flexible Metals Flexible Plastic Flexible Plastic Paper Paper Rigid Plastic Rigid Plastic PET Plastic Bottles PET Plastic Bottles |

| Bale Size |

|

|

|

| Machine Size |

|

|

|

| Feed Opening |

|

|

|

| Bale Weight |

|

|

|

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.