How to Improve Business Waste Management

Every business generates waste and doing so costs money. The true cost of waste is not simply the cost of discarded materials – it encompasses, disposal costs, unnecessary use of energy, storage fees and labour time. The actual cost of such waste for UK companies is typically 4 – 5% of turnover, and can be as high as 10%[1]. There is a common misconception that ‘going green’ will end up costing businesses more money. The truth is that by managing waste efficiently and recycling more can lead to cost savings and minimise your environmental impact at the same time. In addition to this, your business can profit from a host of other benefits including:

Reduction in Landfill Tax

Since 2017 landfill tax has risen 11.55% to £91.35 and is set to rise a further 3% in 2020 [2]. A ~15% increase in costs in 3 years shouldn’t be ignored.

Achieve ISO 14001 Status

Managing waste effectively is a key component of this standard. Deploying effective waste management solutions will ensure your organisation not only achieves but also maintains its status.

Corporate Social Responsibility

In a 2018 survey of 2000 adults, 67% of participants would be more likely to purchase brands that are more sustainable than those that are less sustainable [3]. This trend is only set to increase, therefore a sustainable image is more important than ever.

Generate Revenue

Recyclables can be collected and re-sold to offset costs and generate income. Once baled materials such as cardboard, plastic, paper, etc. can be sold or collected for free.

Minimise Environmental Impact

Production of raw materials, transportation and biodegrading waste all emit greenhouse gases into the atmosphere. By reducing your business waste you’re minimising the impact on the environment.

Safer Working Environment

Compacted waste takes up significantly less space and requires less storage space. A clean and tidy workplace minimises trip hazards and creates a safer environment for employees.

Steps to Reducing Business Waste

With so many incentives to improving waste management, you might be wondering how can I implement this to my business? To answer that question, we’ll introduce the Waste Hierarchy Model. This philosophy aims to not only reduce the disposal of waste but aims to prevent it from being produced in the first place. The hierarchy outlines the most to least favoured steps to handling waste.

Site Audit

Before we jump into steps to reduce your business waste we must first know what you’re handling with in the first place. Completing a full site audit will help you understand how waste occurs in the first place and how it can be prevented or managed.

If this task seems daunting, don’t fret. We offer a completely free, no-obligation on-site audit. During this visit, we’ll analyse all of your waste streams and recommend a solution that will best satisfy your requirements. We have over 20 years experience in waste management so rest assured we’ll find the right fit for you.

The Waste Hierarchy

Reduce

The most cost-effective and environmentally friendly solution is to eliminate waste in the first instance. Organisations should look to modify their current practices to reduce the amounts of waste generated by changing the design, manufacturing, purchase, or use of certain materials.

Supply Chain Analysis

A sure-fire way to reduce waste is to ensure it never reaches your business in the first place. Work closely with your suppliers to eliminate unnecessary packaging and consider suppliers that offer reusable or sustainable packaging. Some suppliers will even collect excess packaging to be re-used for future orders.

Product Analysis

In addition to looking at your supply chain, focus can be directed towards internal processes. Can less waste be produced or different materials be used during production? By looking for opportunities in reduction you can stop eliminate sources of waste.

Go Paperless

Try to utilise Email as much as possible and only print when necessary. When you need to print cut usage in half by printing double-sided. In addition to this, stop paper from coming into the business by ensuring you unsubscribe from any unwanted mail shots or flyers.

Ditch Single-Use Plastic

Use washable cups for drinks as an alternative to plastic or paper ones. Encourage employees to use reusable bottles instead of bottled water.

Re-use

By reusing products, materials and tools you extend their useful life span, thus delaying the final disposal of these items. Businesses can look to implement this by repairing, refurbishing or washing appliances, furniture, and building materials. Anything that can’t be re-used by your own business could be donated to other organisations.

Recycle

Recycling is the process of transforming waste material back into its raw-form so it can be re-integrated into the production line and give rise to new products. This prevents pollution and saves energy.

At Landfill alternatives, we can help you during the recycling stage. In most cases, we can help eliminate all waste that goes to landfill.In order to achieve this, we implement a range of industry-leading machinery such as Balers & Crushers into your workplace that can capture material such as paper, cardboard and plastic and process it ready for recycling. Even small businesses that only produce low volumes of recyclables can benefit from baling waste.

Our smallest Vertical Baler; the can create bales up to 25kg in weight and was designed to fit into the tightest of spaces – inside or outside. Multiple streams of waste can be baled including; paper, cardboard, plastic, flexible metals and plastic film, etc. Once baled the material is collected and sent to recycling centres. Depending on the amount of waste this is either free or can actually produce a rebate, effectively turning what was once a disposal cost, into a revenue stream.

Capturing Waste

To produce bales, you’ll need to segregate each stream of material. This can easily be accomplished by implementing a clear process that is simple for everyone involved to follow. We recommend you consider the following points when devising your strategy;

Engage Employees

Once a Baler is installed it is crucial to ensure that staff training includes awareness of good waste management and the specific measures used at your business. Try to make waste reduction part of the company culture. Go even further and consider incentivising staff for re-using material by sharing the financial savings.

Sort at Source

Implement collection points where waste is generated. We sell Stuffer Frames, which are metal frames that hold sacks for waste collection. They allow for easy collection and segregation of polythene, strapping and paper. These are lightweight and moveable and should be pleased at the source of waste for easy separation of materials.

Minimise Contamination

Recycling centres are imposing stricter restrictions on contamination and will only accept uncontaminated material. Ensure your efforts aren’t jeopardised by placing a waste container near to all recycling containers to prevent recycling containers being used for general waste.

Consistent Labelling

Further reduce contamination by clearly labelling waste containers on-site to promote effective segregation. Reduce confusion by using consistent image-heavy labelling across the entire site. The use of imagery or icons will assist any members of staff whose English is not their first language.

Monitor & Review

Once your waste management strategy is in place you must ensure it is monitored and reviewed frequently. Check containers to ensure that the proper materials are going into them. If problems exist, identify the cause and implement a solution to ensure procedures are adhered to.

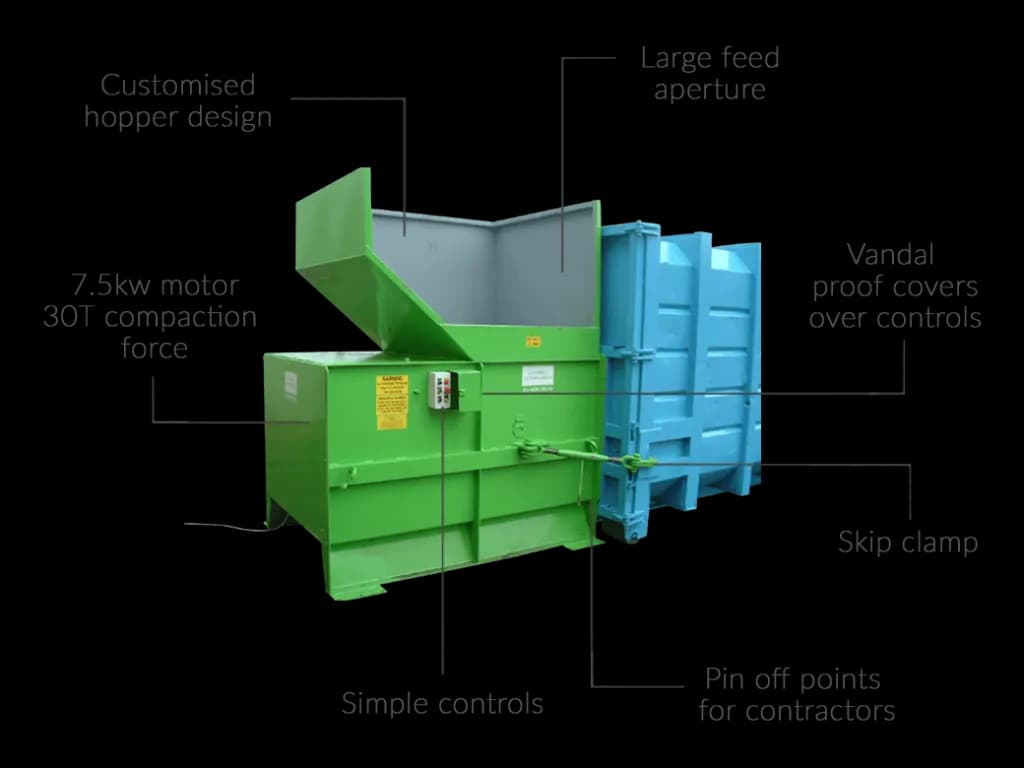

Landfill

The final stage in the hierarchy when all other options have been exhausted is disposal to landfill. Even if your business is unable to completely close the loop, we can still help. We have a comprehensive range of static, portable and specialist that will ensure any waste sent to Landfill is fully compacted.This minimises the number of collections required, which means fewer trucks on the road resulting in a cost-saving and lower C02 emissions. Many of our customers have experienced this first hand including the facilities manager at Wicks who saw a reduction of skip collections by a factor of 7:1.

“We have not changed any of our operating systems so it has achieved this £15,000 saving per annum with no disruption. Landfill Alternatives were very knowledgeable and gave us a number of options to process the waste and how to dispose of it”. – Read More.

Our Expertise

LFA has helped divert over 1,000,000 tonnes of waste from Landfill – with many of our clients achieving nil to landfill. This task may seem daunting but all you need is the right machinery and efficient processes in place. The initial time and investment required is quickly recovered by staff efficiency savings and the additional revenue generated from waste rebates.

If you don’t currently have a waste management plan, or if you believe yours could be improved, speak to us. We’re happy to offer advice and carry out a no-obligation on-site audit to see how your waste processes could be streamlined to increase efficiency, reduce costs and become more sustainable.