LFA 251 – Medium Vertical Baler

The LFA 251 is our half mill size vertical baler that creates bales up to 280kg (depending on material). It is an ideal machine for medium/large quantities and size of material due to its 1160 x 700mm feed opening and 16t compaction force. The LFA 251 has an auto eject feature making bale ejection easy. With an IP rating of 65, it can withstand all forms of weather so it can be sited inside or outside.

The most common types of materials baled are cardboard, plastic film, dry waste and paper, but it can also bale other materials.

Product Details

| Product Dimensions | |

|---|---|

| Overall Width | 1720mm |

| Overall Height | 2440mm |

| Overall Depth | 950mm |

| Overall Weight | ~1100kg |

| Feed Opening Width | 1040mm |

| Feed Opening Height | 590mm |

| Technical Specification | |

|---|---|

| Compaction Force | 16T |

| Motor | 4kW |

| Cycle Time | 55 Seconds |

| Noise Level | 60dB |

| Bale Full Indicator | Grill |

| Feed Door | Side Hinged |

| Electricity Supply | 3 Phase, 415V, 16A |

The baler can be specified with a vandal proof cover over the controls and a lockable feed door. It can also be used as a can/drum crusher by inserting one our can crusher tables. The compaction cylinder can be dropped to get it through areas with restricted access. For further customisation, contact us and we will try to meet all requirements.

Typically, the minimum amount of recyclable material per week to gain a cost saving would be either:

- 1100ltr wheelie bin(s) – Four DMR (Dry mixed recyclables) or three GW (General waste)

- FEL (Front end loader) skip(s) – One DMR or ½ of one GW

- REL (Rear end loader) skip(s) – Half of one DMR or ¼ of one GW

Once baled, the rebate received for the bales would typically be over £50 per ton depending on the material and quantity stored.

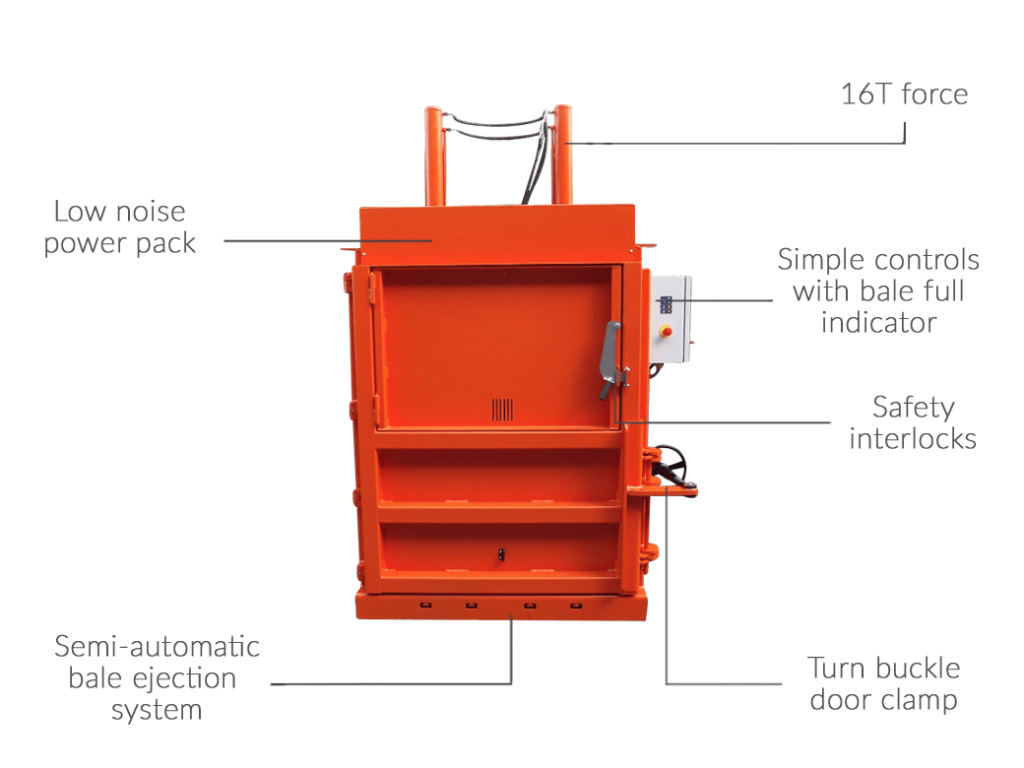

Features

- E-stops

- Twin cylinder

- Automatic cycle

- Bale twine cutter

- Bale full indicator

- Strapping guide slots

- Side hinged feed door

- Safety interlocked doors

- Turn buckle door opener

- Simple, easy to operate controls

- Auto eject for easy bale removal

- Rated IP65 so safe to be sited inside or out

- 36 Retention teeth inside the front door and chamber

Benefits

- Saves on labour from reduced material handling

- Reduces storage space required for bulky waste

- Reduces the need to flat pack/break down material

- Reduces carbon footprint and complies with ISO 14001

- Reduces disposal costs and able to generate an income for material

- Leads to a tidier working environment which improves health and safety

The LFA 251 takes roughly 30 seconds to set up and 3 minutes to tie off a bale, making it quick and easy to use.

Step 1 – Setup

When first using the machine, attach the bale twine reels to the back of the machine and guide the four straps through the rear of the machine into the chamber. Pull the twine through, make a loop and attach it onto the four hooks that are positioned on the front of the machine. Lay the twine into the guide slots on the base making sure they are taught. Close the door and feed the material.

Step 2 – Feeding

This step is straight forward – open the top feed door and throw the material into the chamber, making sure it is spread evenly (there is no need to flat pack the material as the baler will do the work). Close the feed door and press the green ‘go’ button. The plate will automatically run a full cycle compacting all of the material into the bottom of the chamber and catching on the retention teeth. The plate then returns to the resting position ready for the next load. (If at any point the door is opened, the machine will cut out for safety precautions).

Step 3 – When is the bale full?

There is a bale full grill positioned on the feed door, when the plate is under full compaction and the plate sat in the middle of the grill is visible, the bale is full and ready to be tied off. Repeat step 2 until this happens. If opting for the automatic bale full stop option, the baler will stop and signal that the bale is full and ready to tie off.

Step 4 – Tying off the bale

With the plate in its resting position at the top of the chamber, open the feed door (using our twine hook), bring the four twines across the top of the bale and cut the twine at the correct length. Feed the twines through the slots in the bottom door and lay the other twines that are still attached to the reel on the top of the material ready for the next bale. Close the feed door and press the ‘down’ arrow button for the plate to compact and stay down. Now that the material is under compression, detach the loop end of the twine from the hook and pull the cut end through. Pull it tight and tie off. Repeat this on the other twines.

Step 5 – Ejecting the bale

Once the bale is created, it needs to be ejected. Open both doors and place a pallet in front of the baler. The baler has a pin that automatically slides into place interacting with the ejection chains when the door is open. Hold down the two bale ‘eject’ buttons and the plate will start rising with the ejection chains. The bale will start tipping and with momentum will slowly roll onto the pallet. The bale now weighs up to 280kg sat on a pallet ready to be stored for collection.

As simple as that! It probably takes longer to read the operation than to implement it. As part of the package, one of our trusty engineers will come to site and show the team how to do this in person. Training certification can be supplied if required.

*Note – Refurbished models may vary in its operation slightly, but the principle will remain very similar.

LFA 251 – Medium Vertical Baler Brochure

Interested in learning more about the LFA 251 – Medium Vertical Baler? Leave your details below to get an instant free copy of our brochure.

Benefits of Baling

-

Reduce carbon footprint and comply with ISO 14001

-

To reduce storage space required for bulky waste

-

Reduce disposal costs and receive maximum income on the baled material

-

To lead to a tidier work environment which improves health and safety

-

To reduce the need to flat pack/break down material

-

To save on labour from reduced material handling

More Questions Than Answers?

We appreciate that our comprehensive range of machinery can sometimes make it difficult to find the right machine to suit your requirements.

Our Product Finder tool makes it easy to find the perfect Baler, Crusher or Compactor to satisfy your business requirements.

Show MeRequest a callback

Prefer to speak to us in person? Then leave your details below and a member of the team will be in touch shortly.