LFA UCGC

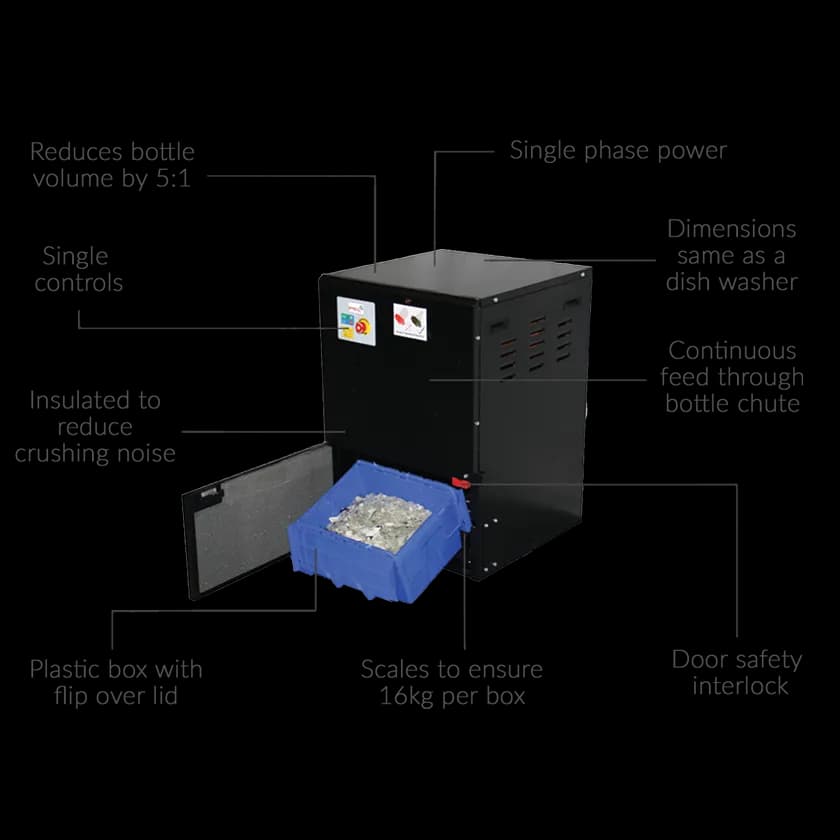

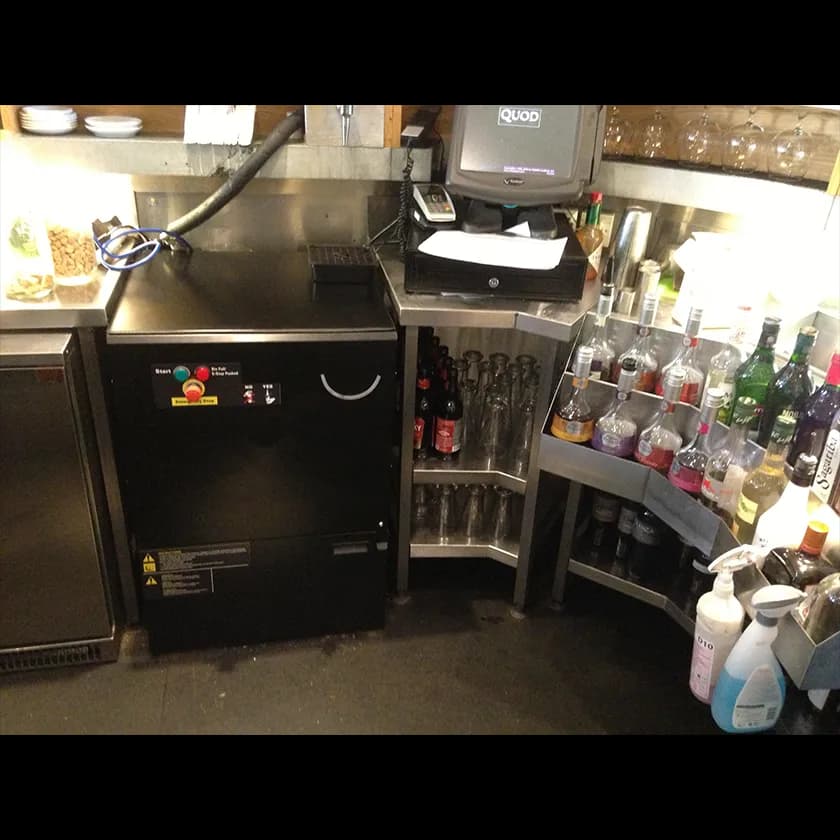

The LFA UCGC (Under Counter Glass Crusher) reduces glass volume by up to 5:1, cutting waste collections significantly. Designed to fit the same size as a standard kitchen unit, it features a foam-encased hammer to minimise noise, making it ideal for pubs, hotels, and restaurants.

Glass bottles can be processed directly at the bar, with the crushed glass (cullet) collected in a plastic tote box located behind the lower door. The tote holds up to 95 bottles or 16kg of cullet, and built-in scales automatically indicate when the box is full by locking the bottle chute.

Suitable For

Glass

Glass

Arrange a Callback with an Expert

We can help you pick the right machine to save your business money on waste disposal.

Compare with Similar Machines

This Machine | Larger | |

|---|---|---|

| Price | From £21 P/W | From £26 P/W |

| Throughput | Low | Low |

| Suitable For |  Glass Glass |  Glass Glass |

| Machine Size |

|

|

| Feed Opening |

|

|

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.