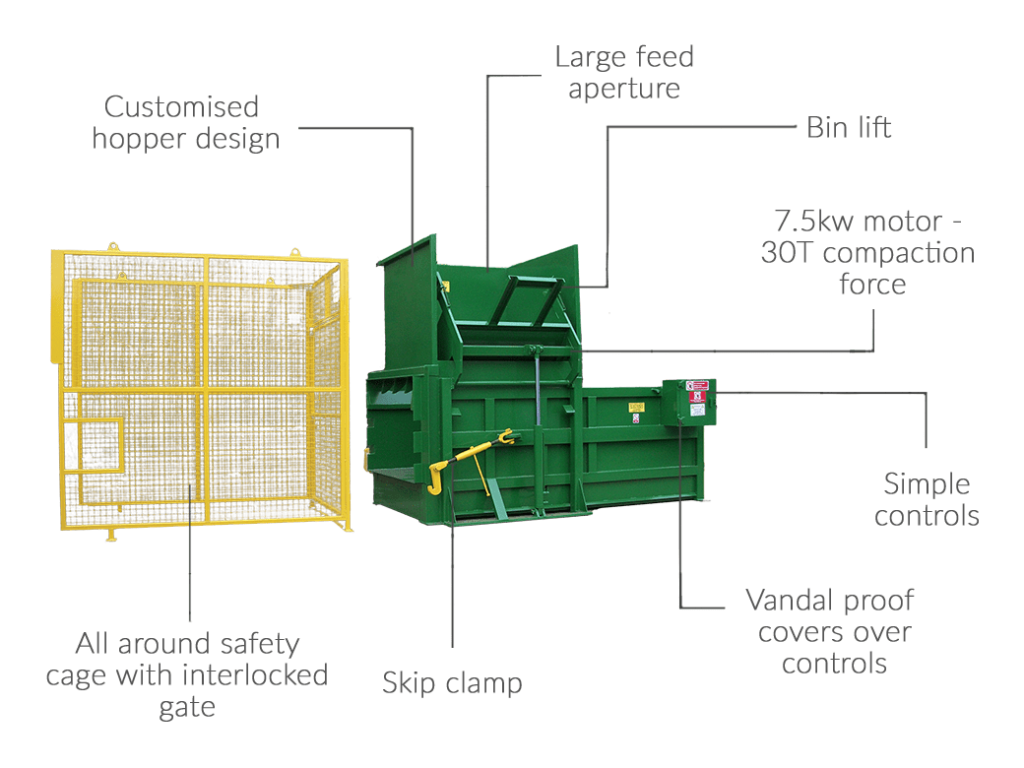

LFA SC 2 BL – Short Static Compactor – Bin Lift

The LFA SC 2 BL is our entry level, short static compactor with an integrated bin lift system. By using the LFA SC 2 BL, it ensures that charges are correct for disposal instead of being overcharged for under capacity skips and bins. Boasting a high 30t compaction force the LFA SC 2 BL is capable of achieving payloads of up to 10t into a 35-yard RoRo skip. The straight push ram is a low maintenance system which has a fast cycle time of 54 seconds meaning you are able to compact up to 107m³ of waste per hour. Static compactors are commonly used for dry general waste, but it can be used on lots of different applications where compaction is required. The integrated bin lift is great for reducing manual labour and to easily feed the compactor. As standard it is able to lift 1100L wheelie bins via its pintel up to 450kg. The bin lift can be specified with an all-round safety cage.

Product Details

| Product Dimensions | |

|---|---|

| Overall Width | 3760mm |

| Overall Height | 1300mm |

| Overall Depth | 2220mm |

| Overall Weight | ~2800kg |

| Feed Opening Width | 1200mm |

| Feed Opening Depth | 1430mm |

| Technical Specification | |

|---|---|

| Compaction Force | 30T |

| Motor | 7.5kW |

| Cycle Time | 54 Seconds |

| Ram Penetration | 350mm |

| Charge Box Depth | 940mm |

| Charge Box Volume | 1.61m³ |

| Max Volume Displacement Per Hour | 107m³ |

| Electricity Supply | 3 Phase, 415V, 32A |

The compactor can be specified with a 75% and 100% full light and we can fabricate the feed hopper to hit your needs. A cage can be attached to it for extra precaution. To destroy material, we can supply a pre-crush variant to destroy products or force liquids out of bottles/cans. For further customisation, contact us and we will try to meet all requirements.

Typically, the minimum amount of waste per week to gain a cost saving would be either:

- 1100ltr wheelie bins – Fifteen GW (General waste)

- FEL (Front end loader) skip(s) – Three GW

- REL (Rear end loader) skip(s) – Two GW

Features

- E-stops

- Skip clamps

- ¾ full indicator

- Automatic cycle

- Integrated bin lift system

- Simple, easy to operate controls

- Hydraulic pack separate from waste

- Powerful 30 tonne compaction force

- Rated IP65 so safe to be sited inside or outside

- Low maintenance straight ram compaction method

Benefits

- Helps prevent fly tipping

- Keeps the yard much tidier

- Reduces waste disposal costs

- Reduces contractor traffic on site

- More environmentally friendly

- Fast interchange of skips so minimal down time

- No longer being charged for air voids in skips/bins

- Reduces carbon footprint and complies with ISO 14001

The LFA SC 2 BL is extremely easy to use and requires very little manual work.

Step 1 – Setup

When installing, the LFA SC 2 BL must be bolted to the floor by one of our engineers. Once installed, the contractor will supply and attach an enclosed 35yd RoRo hook lift skip to it via the compactor’s clamps.

Step 2 – Feeding

Wheel the bins full of waste up to the compactor. The operator holds the bin lift and ‘up’ buttons on the control panel and the integrated bin lift will start lifting the bin up via its pintels, the waste from the bin will then be tipped into the charge box. On the control panel the operator will then hold down the’ bin lift’ and ‘down’ buttons at the same time to return the bin to the floor and press the green ‘go’ button to start the compaction cycle. The straight ram will then compact the waste from the charge box into the attached skip. In its standard setup this will cycle 3 times but can be configured to run more/less or on a timer.

Step 3 – When is the skip full?

The compactor has an indicator to notify the operator when the skip is ¾ full. Once this illuminates, the operator can calculate when it will be full and when the skip needs to be collected by the waste contractor.

Step 4 – Waste removal

The contractor will arrive on site with a hook lift vehicle and an empty skip, they will set down the empty skip to one side and then start inserting pinning bars to stop the compacted waste from ejecting out of the skip. They will loosen the clamps and detach the skip from the compactor, they then pull the skip away slightly and attach a cover over the opening on the skip to ensure no loose debris falls out in transportation. The full skip is then moved out of the way and set down, the empty skip is then picked back up, moved into place and clamped to the SC 2 BL ready for compaction. The contractor then picks up the full skip and takes it away.

As simple as that! It probably takes longer to read the operation than to implement it. As part of the package, one of our trusty engineers will come to site and show the team how to operate it in person. Training certification can be supplied if required.

*Note – Refurbished models may vary in its operation slightly, but the principle will remain very similar.

LFA SC 2 BL – Short Static Compactor – Bin Lift Brochure

Interested in learning more about the LFA SC 2 BL – Short Static Compactor – Bin Lift? Leave your details below to get an instant free copy of our brochure.

Benefits of Compacting

-

To reduce waste disposal costs

-

To keep the yard much tidier – no mess or leakage

-

To gain a rebate of recyclable material

-

To prevent fly tipping

-

To have less contractor traffic on site

-

To be more environmentally friendly

More Questions Than Answers?

We appreciate that our comprehensive range of machinery can sometimes make it difficult to find the right machine to suit your requirements.

Our Product Finder tool makes it easy to find the perfect Baler, Crusher or Compactor to satisfy your business requirements.

Show MeRequest a callback

Prefer to speak to us in person? Then leave your details below and a member of the team will be in touch shortly.