LFA Digestor

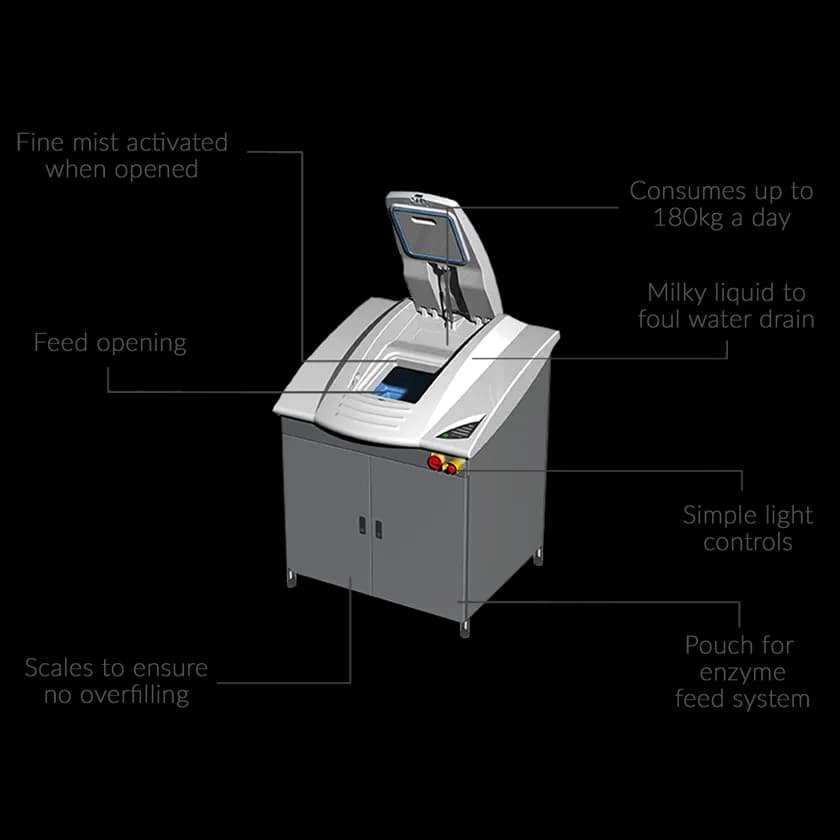

The LFA Digester is a food waste solution that breaks down soft biodegradable materials, converting them into a grey water effluent that can be safely discharged directly into the drainage system.

Replicating the function of a stomach, the machine gently churns food waste while mixing it with warm, enzyme-rich water. These enzymes bind to carbohydrates, fats, and proteins, catalysing their breakdown and producing a safe grey water output.

The digester is best suited for soft biodegradable waste such as cooked and uncooked meat, fish, vegetables, bread, and rice. It is not designed for heavily fibrous materials such as bones and fruit husks. Capable of processing up to 180kg of food waste per 24 hours, the LFA Digester delivers a significant reduction in disposal costs.

Suitable For

Food Waste

Food Waste

Arrange a Callback with an Expert

We can help you pick the right machine to save your business money on waste disposal.

Compare with Similar Machines

This Machine | Smaller | |

|---|---|---|

| Price | From £47 P/W | From £51 P/W |

| Throughput | Medium | High |

| Suitable For |  Food Waste Food Waste |  General Waste General Waste |

| Machine Size |

|

|

| Feed Opening |

|

|

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.