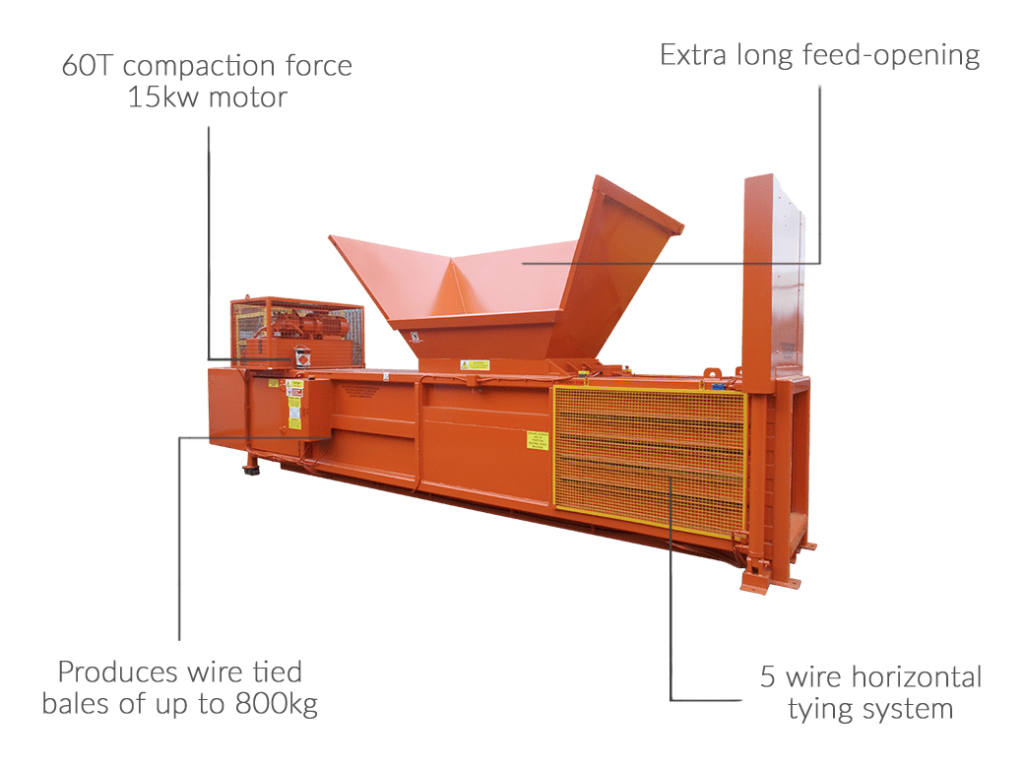

LFA 850 H – Horizontal Baler

The LFA 850 H is one of our largest semi-automatic horizontal balers which can produce bales of cardboard and plastic film in excess of 1t due to its high 60t compaction force and large bale sizes. The upgraded 15kW motor runs a fast 50 second cycle which, in tandem with other features, achieves throughputs of up to 3t/hr. The extra-large 5mm thick, 2000mm x 1050mm hopper is perfect for large bulky materials, and for feeding via mechanical systems like tele-handlers, bin lifts, conveyors etc. The 5 wire, horizontal tie system means tying off bales is quick and simple which helps achieve the greater throughputs. The second bale ejection method is a simple system which uses the material from the next bale to push out the already created bale. Although this is a great economical system, it is best suited for one type of material as baling two or more types of material allows cross contamination. The most common types of materials baled are cardboard, soft and rigid plastics, RDF and paper, but it can also bale other materials.

Product Details

| Product Dimensions | |

|---|---|

| Overall Width | 7510mm |

| Overall Height | 2460mm |

| Overall Depth | 1750mm |

| Overall Weight | ~7000kg |

| Feed Opening Width | 2000mm |

| Feed Opening Depth | 1050mm |

| Technical Specification | |

|---|---|

| Compaction Force | 60T |

| Motor | 15kW / 22kW |

| Cycle Time | 50 / 35 Seconds |

| Throughput | 3 T/Hr |

| Wire Ties | 5 |

| Tying Direction | Horizontal |

| Bale Ejection Method | Second Bale Eject |

| Noise Level | 80dB |

| Electricity Supply | 3 Phase, 415V |

We can modify the LFA 850 H baler to your specific needs. We can attach an integrated bin tipper, door dampener and retention claws. We can also adapt the hopper to suit your feeding method, the shearing blades to suit your material and we can also upgrade the motor to decrease the cycle time. For further customisation, contact us and we will try to meet all requirements.

- Features

- E-stops

- Automatic cycle

- Anti-whip hoses

- Wire guide slots

- Magic eye sensor

- Power pack cover

- Vandal proof door

- Bale full/jam beacon

- Dual pressure switch

- Start-up alarm beacon

- Manual forward/reverse

- Full bale ejection system

- Hydraulic Portcullis Door

- Automatic bale full system

- Upgraded 5mm flared hopper

- 5-wire horizontal tying system

- Simple, easy to operate controls

- Interlocked access door on hopper

- Retention claws inside the chamber

- Economical second bale eject system

- Aggressive ram head with sheer blades

- Extra-large feed opening for bulky materials

- Rated IP65 so safe to be sited inside or outside

- Hardox® castellated floor for low maintenance and long life

Benefits

- Saves on labour from reduced material handling

- Reduces storage space required for bulky waste

- Reduces the need to flat pack/break down material

- Reduces carbon footprint and complies with ISO 14001

- Produces mill-size bale dimensions to optimise transport loads

- Leads to a tidier working environment which improves health and safety

- Reduces disposal costs and able to generate the maximum income for material

The LFA 850 H is very easy to use.

Step 1 – Feeding

This step is straight forward – press the green ‘go’ button to put the baler into idle mode. Start feeding material into the hopper. A magic eye sensor sits at the bottom of the hopper and once the sensor detects material, the baler starts up and runs a full cycle compacting all of the material into the bale chamber. The material catches on the retention claws preventing it from springing back into the charge box. Continue feeding material into the hopper as it will sit on top of the ram head dropping into the charge box when the ram returns.

Step 2 – When is the bale full?

This baler has an auto stop feature so when the bale is full, lights flash on the control panel, the ram head stays forward, and the material stays under compression.

Step 3 – Tying off the bale

This baler is a horizontal tie which makes this step very easy. At the side of the bale chamber there are slots where you can see the ram head which has bale wire channels. Thread the wire (straight end first) through this channel and the wire will come out to the other side. There are slots in the door, so both ends of the wire now need to be threaded through these. When both ends of the wire are together, thread the straight end of the wire through the loop end, pull the wire tight and wrap the wire around itself 3-4 times. Repeat this on the other wires.

Step 4 – Ejecting the bale

Once a full bale has been created, it need to be ejected. Next to the door there are controls for the hydraulic door, press on both of these buttons until the door is unclamped. Swing the door open past 90° and place a pallet in front of the baler. On the main control panel, press the reverse button until the ram head is all the way back. Feed the machine with material and press the forward button. The material just fed into the machine will start pushing the bale out. Do this 3-4 times until the bale is fully ejected. You now have a bale sat on a pallet ready to be stored for collection. Close the door and hold down the two hydraulic door buttons to clamp the door shut.

As simple as that! It probably takes longer to read the operation than to implement it. As part of the package, one of our trusty engineers will come to site and show the team how to operate it in person. Training certification can be supplied if required.

*Note – Refurbished models may vary in operation slightly, but the principle will remain very similar.

LFA 850 H – Horizontal Baler Brochure

Interested in learning more about the LFA 850 H – Horizontal Baler? Leave your details below to get an instant free copy of our brochure.

Benefits of Baling

-

Reduce carbon footprint and comply with ISO 14001

-

To reduce storage space required for bulky waste

-

Reduce disposal costs and receive maximum income on the baled material

-

To lead to a tidier work environment which improves health and safety

-

To reduce the need to flat pack/break down material

-

To save on labour from reduced material handling

More Questions Than Answers?

We appreciate that our comprehensive range of machinery can sometimes make it difficult to find the right machine to suit your requirements.

Our Product Finder tool makes it easy to find the perfect Baler, Crusher or Compactor to satisfy your business requirements.

Show MeRequest a callback

Prefer to speak to us in person? Then leave your details below and a member of the team will be in touch shortly.