Find the Best Cardboard Baler for Your Needs: A Comparative Guide

In today’s eco-conscious business world, efficient waste management is not just a necessity—it’s a responsibility. For companies dealing with large volumes of cardboard waste, choosing the right cardboard baler can make a significant difference in operational efficiency, cost savings, and environmental impact. But with various types of cardboard balers available in the market, how do you determine which one is perfect for your business?

Overview of Cardboard Balers

Before diving into the specifics, let’s understand what cardboard balers are and why they’re essential. Cardboard balers are machines designed to compress and bundle cardboard waste into compact, manageable bales. These devices play a crucial role in reducing the volume of waste, making storage and transportation more efficient, and facilitating recycling processes.

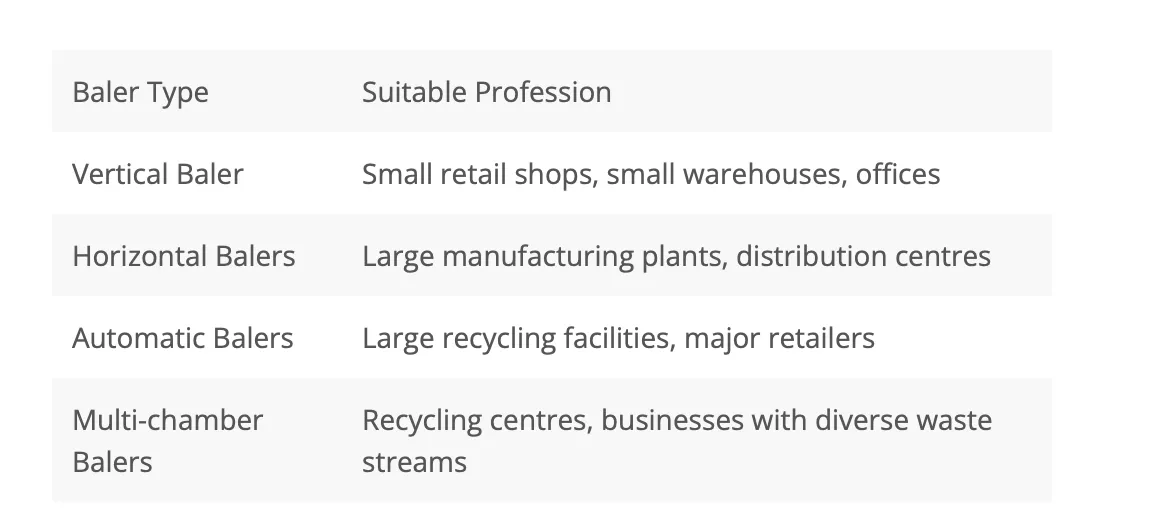

Types of Cardboard Balers

1.Vertical Balers

Vertical balers are among the most common types used in various businesses. As the name suggests, these balers operate vertically, with the compression plate moving up and down to compact the cardboard.

Description: Vertical balers typically have a smaller footprint, making them suitable for businesses with limited space. They require manual loading of cardboard into the chamber, and once full, the operator activates the compression cycle.

Advantages:

- Space-efficient design

- Lower initial cost compared to horizontal balers

- Ideal for small to medium-sized businesses

- Easy to operate and maintain

Best use cases: Retail stores, small warehouses, and businesses with moderate cardboard waste output.

2. Horizontal Balers

Horizontal balers are larger machines designed for high-volume cardboard waste processing.

Description: These balers compress cardboard horizontally, allowing for continuous feeding of material. They often feature automatic tie-off systems and can produce larger, denser bales than vertical balers.

Advantages:

- High-volume processing capability

- Produces larger, more compact bales

- Requires less frequent bale removal

- More efficient for businesses with constant cardboard waste flow

Best use cases: Large distribution centres, recycling facilities, and industrial settings with high cardboard waste output.

3. Automatic Balers

Automatic balers represent the pinnacle of efficiency in cardboard waste management.

Description: These balers automate most of the baling process, from feeding to compressing and tying off bales. They often incorporate conveyor systems for continuous operation.

Advantages:

- Minimal human intervention required

- High throughput and efficiency

- Consistent bale size and density

- Reduced labour costs

Best use cases: Large-scale operations with continuous cardboard waste generation, such as major distribution centres or manufacturing facilities.

4. Multi-chamber Balers

Multi-chamber balers offer versatility in waste management by allowing different materials to be baled separately.

Description: These balers feature multiple compression chambers, each dedicated to a specific type of recyclable material.

Advantages:

- Allows simultaneous baling of different materials

- Efficient for businesses dealing with various recyclables

- Helps maintain the purity of recycled materials

Best use cases: Businesses that handle multiple types of recyclable materials, such as cardboard, plastic, and paper.

Which Baler is best suited for you?

Key Features to Consider

When selecting a cardboard baler, several key features should be taken into account:

- Size and Capacity: Consider the physical dimensions of the baler and its bale production capacity. Ensure it fits your available space and can handle your cardboard waste volume.

- Power and Efficiency: Look at the baler’s compression force and cycle time. More powerful balers can create denser bales, while faster cycle times increase overall efficiency.

- Ease of Use and Maintenance: Consider the baler’s operational complexity and maintenance requirements. User-friendly controls and easy access for maintenance can save time and reduce downtime.

- Safety Features: Prioritise balers with robust safety features such as emergency stop buttons, safety interlocks, and proper guarding to protect operators.

- Buying vs. Renting: Consider your long-term needs and financial situation when deciding between buying or renting a baler.Buying offers long-term cost savings and control but requires higher upfront investment. Renting provides flexibility and lower initial costs but may be more expensive over time. Evaluate your waste volume, budget, and future plans to make the best choice.

.

Choose Landfill Alternatives today!

Discover eco-friendly and cost-effective waste management solutions with our range of cutting-edge balers. From compact vertical models to high-capacity horizontal balers, we have the perfect match for your business needs. Unsure which baler is right for you? Try our unique Product Finder feature – it’s quick, easy, and tailored to your specific requirements. Want expert advice? Take advantage of our free site audit, where our specialists will assess your space and recommend the ideal baling solution. Request a call back today!