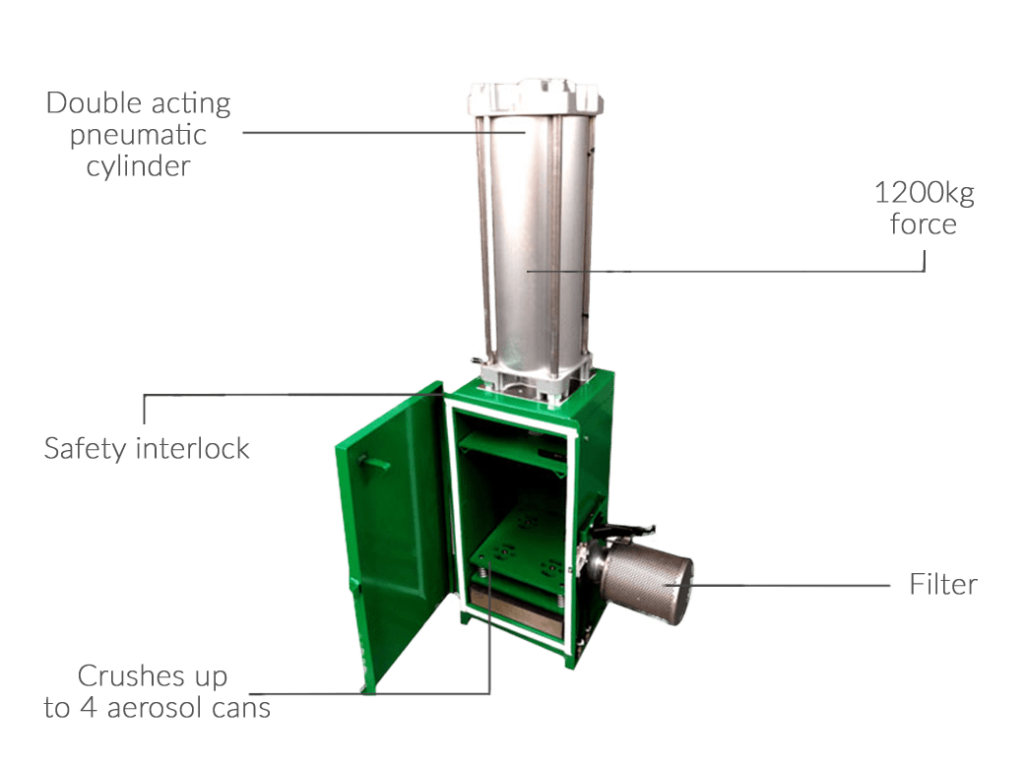

LFA ACC 4 – Aerosol Can Crusher

The LFA ACC 4 aerosol can crusher safely degasses, and crushes aerosol cans up to 80% by using a compaction force of 1.2 tonne. Four cans can be loaded into the chamber at a time with the max size of can being 260mm high. The gases are filtered easily and all LFC’s are decreased through a carbon filter located at the side of the machine making the cans now safe and unhazardous ready for disposal. A conversion plate is included to crush cans up to 5 litres. If required, an air compressor can be supplied.

Product Details

| Product Dimensions | |

|---|---|

| Overall Width | 350mm |

| Overall Height | 1150mm |

| Overall Depth | 300mm |

| Overall Weight | ~40kg |

| Chamber Width | 235mm |

| Chamber Height | 260mm |

| Chamber Depth | 235mm |

| BORE SIZE | 160mm |

| SPOKE LENGTH | 350mm |

| Technical Specification | |

|---|---|

| Compaction Force | 1.2T |

| Aerosol Capture Method | Carbon Filter |

| Bore Size | 160mm |

| Stroke Length | 350mm |

| Cans Crushed at a time | 2 or 4 |

| Max Aerosol Size Height | 260mm |

| Air Input | 100psi |

| Air Connection | ¼" BSP |

Free training, installation and delivery is offered nationwide.

Typically, around 50 aerosol cans a week would produce a cost saving.

Features

- Drip tray

- Small footprint

- ATEX compliant

- Can piercing pins

- Pneumatic cylinder

- Full all-round seals

- Safety interlocked door

- Simple, easy to operate controls

Benefits

- Reduces disposal costs

- Reduces can volume by up to 5:1

- Makes aerosol cans non-hazardous

- Waste takes up less space in skips/bins

- Reduces carbon footprint and complies with ISO 14001

- Leads to a tidier working environment which improves health and safety

The LFA ACC 4 is very easy to use. It only takes 15 seconds for a full compaction cycle.

When first setting up the machine, attach a 100-psi airline and turn the lever to allow air to pressurise the cylinder. Open the feed door, take 2 or 4 aerosol cans and remove their caps and spray nozzles. Place them in the machine over the top of the piercing pins, close the door and latch it shut.

Pull the towards you to start compacting the cans. The piercing pins will allow excess gas to release from the cans and travel through the carbon filter. The cylinder will continue compacting until it’s at its maximum pressure. When the cylinder is under compression the door with not be able to be opened for safety purposes. Once you can hear the cans are fully compacted, push the lever away and the cylinder will start retracting. Once at the top open the door and repeat.

As simple as that! It probably takes longer to read the operation than to implement it. As part of the package, one of our trusty engineers will come to site and show the team how to do this in person. Training certification can be supplied if required.

*Note – Refurbished models may vary in its operation slightly, but the principle will remain very similar.

LFA ACC 4 – Aerosol Can Crusher Brochure

Interested in learning more about the LFA ACC 4 – Aerosol Can Crusher? Leave your details below to get an instant free copy of our brochure.

Benefits of Crushing

-

To reduce volume by 5:1

-

To take up less space in your bin/skip

-

To reduce carbon footprint

-

To reduce disposal costs

Free Delivery

Free training, installation and delivery is offered nationwide

7 day Free Trial

We offer a free 7 day trial for all Vertical Balers and Crushers

More Questions Than Answers?

We appreciate that our comprehensive range of machinery can sometimes make it difficult to find the right machine to suit your requirements.

Our Product Finder tool makes it easy to find the perfect Baler, Crusher or Compactor to satisfy your business requirements.

Show MeRequest a callback

Prefer to speak to us in person? Then leave your details below and a member of the team will be in touch shortly.