How do cardboard balers work?

In today’s environmentally conscious business landscape, effective waste management solutions are more crucial than ever. For companies that deal with high amounts of cardboard waste, cardboard balers have emerged as an efficient and cost-effective solution. However, the operation of this equipment can be a little nerve wrecking, furthermore the overall utilisation aspect of these machines including the cost-saving aspects, doubts over buying or renting these machines can be severely confusing. In such situations, a comprehensive guide to waste balers comes to your rescue.

What is a Cardboard Baler?

A cardboard baler is a specialised machine designed to compress large volumes of cardboard waste into compact, manageable bales. These devices play a pivotal role in commercial cardboard recycling, significantly reducing the volume of waste and streamlining the recycling process.

In the UK, cardboard and paper make up a substantial portion of commercial waste. According to the Department for Environment, Food & Rural Affairs (DEFRA), in 2019, the UK generated 12.6 million tonnes of paper and cardboard waste. This highlights the pressing need for efficient recycling solutions like cardboard balers.

How Does a Cardboard Baler Work?

Understanding the cardboard baler operation is key to appreciating its value in waste management. Let’s break down the process step-by-step:

Step 1: Loading the Cardboard

The process begins with loading the cardboard into the baler. Most modern balers have a large opening at the top or front, allowing for easy loading of flattened cardboard boxes. Some advanced models even feature conveyor systems for automated feeding.

Step 2. Compression

Once loaded, the baler’s powerful hydraulic press activates. This mechanism exerts tremendous force on the cardboard, compressing it into a dense, compact form. The pressure applied can range from 20 to 150 tons, depending on the baler model.

Step 3. Tying the Bale

After compression, the cardboard is secured into a bale. Most balers use strong wire or strapping to bind the compressed cardboard. This step is crucial for maintaining the bale’s shape and facilitating easy handling.

Step 4. Removing the Bale

The final step involves ejecting the finished bale from the machine. Many modern balers have automated ejection systems, while others may require manual removal using a forklift or pallet jack.

This entire process significantly reduces the volume of cardboard waste. A typical bale can compress the equivalent of three to four large waste bins worth of cardboard into a single, manageable unit.

Benefits of Using a Cardboard Baler

Implementing a cardboard baler in your waste management strategy offers numerous advantages:

Cost Savings

In the UK, the standard landfill tax rate saw an uptick, rising from £94.15 per tonne in 2020 to £96.70 per tonne in 2021.Implementing a commercial-grade cardboard compactor or baler allows companies to shrink their cardboard waste volume by as much as 90%. This dramatic reduction leads to significant savings in storage space, handling costs, and transportation expenses.

Space Efficiency

Cardboard balers dramatically improve space utilisation. Instead of numerous bulky waste bins cluttering your premises, a single baler can handle the same volume of waste in a fraction of the space. This freed-up area can be repurposed for more productive use, enhancing overall operational efficiency.

Time Efficiency

The time saved by using a cardboard baler is significant. Staff no longer need to manually flatten boxes or make frequent trips to overflowing waste bins. This time can be redirected to more valuable tasks, boosting productivity.

Environmental Impact

From an environmental perspective, cardboard balers are a game-changer. They facilitate easier recycling, reduce the number of waste collections (thereby lowering CO2 emissions from transport), and contribute to a company’s sustainability efforts.

In the UK, the recycling rate for paper and cardboard packaging waste reached 79.1% in 2019. By implementing a cardboard baler, businesses can contribute to improving this rate further, aligning with national sustainability goals.

Types of Cardboard Balers

There are several types of cardboard balers available, each suited to different business needs:

Vertical Cardboard Balers

Vertical balers are the most common type, ideal for businesses with moderate cardboard waste volumes. They have a smaller footprint, making them suitable for locations with limited space.

Vertical balers are ideal for a variety of businesses dealing with moderate cardboard waste volumes. These might include:

- Retail stores: Supermarkets, department stores, and smaller shops that regularly receive stock in cardboard boxes.

- Restaurants and cafes: Establishments that receive frequent deliveries of ingredients and supplies in cardboard packaging.

- Small to medium-sized warehouses: Facilities that handle product storage and distribution, generating a steady stream of cardboard waste.

- Office buildings: Where paper and cardboard waste accumulates from deliveries and everyday operations.

Horizontal Cardboard Balers

Horizontal balers are larger and more powerful, designed for high-volume waste producers. They can handle continuous feeding and are often used in industrial settings or large retail operations.

Horizontal balers are best suited for businesses with high-volume cardboard waste production. These typically include:

- Large distribution centres: Handling massive quantities of products and packaging daily.

- Major retail chains: With significant turnover and frequent restocking needs.

- Manufacturing plants: Especially those in industries like electronics, appliances, or furniture.

- Recycling facilities: Processing large volumes of cardboard from various sources.

- Industrial complexes: With continuous production and packaging operations.

- Large-scale printing and packaging companies: Generating substantial cardboard waste.

- Mega-retailers and superstores: Dealing with enormous inventory and packaging turnover.

Specialist Cardboard Balers

Specialist multi-chamber balers offer versatile waste management solutions. These advanced machines allow businesses to sort and compact different materials simultaneously, improving recycling efficiency. With separate compartments for various waste types, they streamline the recycling process and maximise space utilisation.

Specialist multi-chamber balers are ideal for businesses that generate diverse waste streams and prioritise efficient recycling. These organisations typically include:

- Large retail complexes: Shopping centres or department stores dealing with various packaging materials.

- Mixed-use facilities: Buildings combining retail, office, and residential spaces.

- Hospitals and healthcare centres: Managing different types of waste, including cardboard, plastic, and confidential paper.

- Universities and large educational institutions: Handling diverse waste from multiple departments and facilities.

- Corporate campuses: With various offices and services generating different waste types.

- Food processing plants: Dealing with cardboard, plastic, and organic waste.

Choosing the Right Cardboard Baler for Your Business

Selecting the appropriate baler for particular needs depends on several factors:

- Waste Volume: Assess how much cardboard waste your business generates regularly.

- Available Space: Consider the physical space you can allocate to a baler.

- Budget: Balance the initial investment against long-term savings and benefits.

- Operational Needs: Think about factors like ease of use, maintenance requirements, and integration with existing processes.

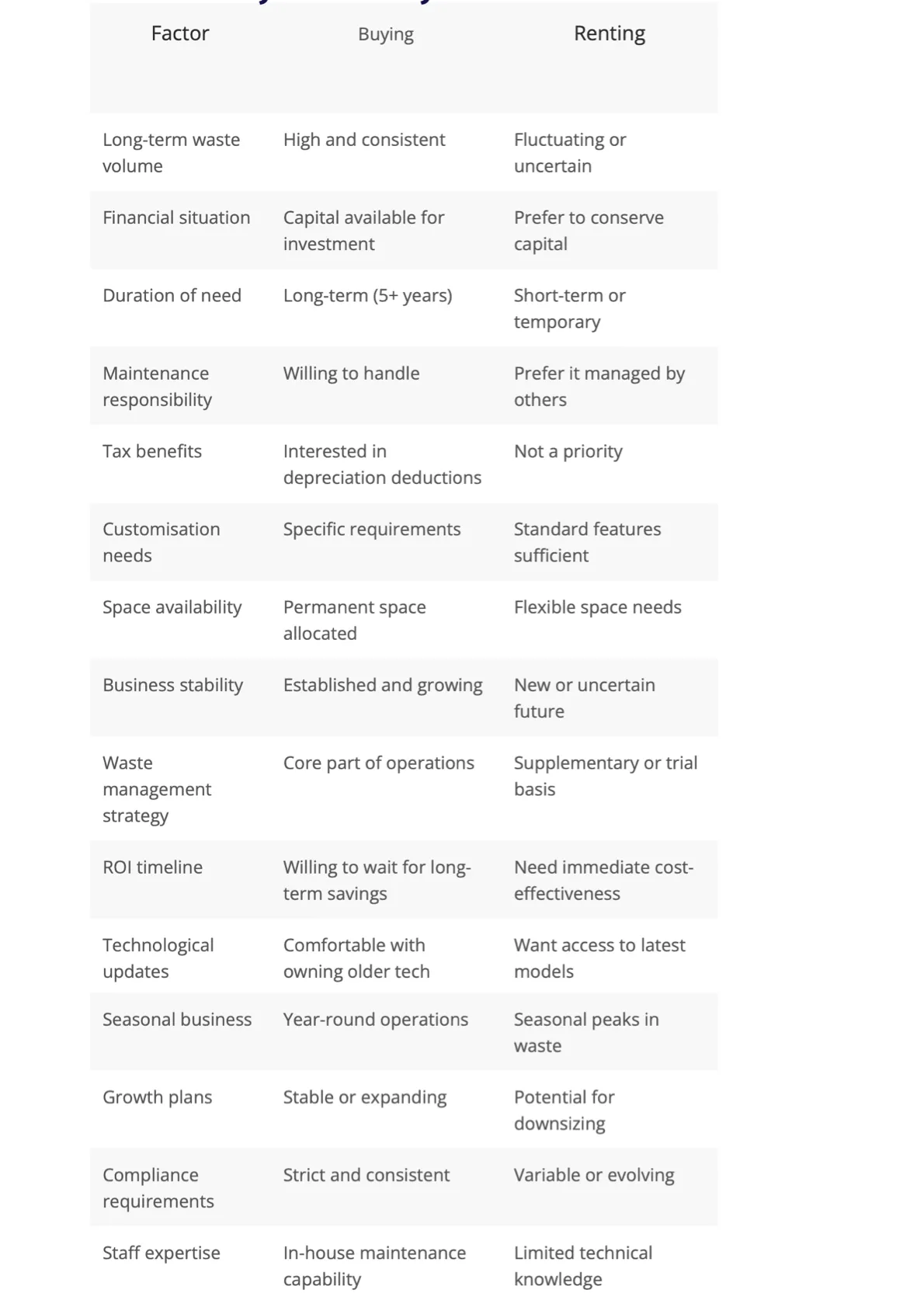

Should I buy or rent my Cardboard Baler?

Case Studies and Testimonials

Know how UK businesses have revolutionised their waste management with different baler solutions, addressing unique challenges and achieving significant operational improvements and cost savings.

NYK Logistics in Mansfield tackled rising waste costs by implementing a vertical baler solution from Landfill Alternatives. The LFA 151 mid-range baler efficiently compresses cardboard into 150 kg blocks, while plastic film is separately baled. This system, along with paper separation in offices, streamlined recycling processes, reduced waste expenses, and generated rebates.

Paperchase’s Thrapston warehouse upgraded from a vertical to a LFA H.FE horizontal baler to handle increased cardboard waste. This streamlined operation eliminated the need for a full-time laborer, as staff could directly dispose of cardboard. The large hopper processes boxes without pre-folding, producing consistent 450kg mill-acceptable bales, improving efficiency and storage.

Climatec Windows in Southend-on-Sea enhanced their environmental practices by installing a twin-chamber recycling compactor from Landfill Alternatives Ltd. This specialist baler, chosen after a two-week trial, allows simultaneous compaction of cardboard and polythene packaging waste. The system proved to offer substantial savings by efficiently segregating and processing different recyclable materials.

Frequently Asked Questions

- How much can a cardboard baler save my business?

Savings vary depending on your waste volume and current disposal costs. However, many businesses report cost reductions of 40-80% on their waste management expenses.

- Are cardboard balers difficult to operate?

Most modern cardboard balers are designed for ease of use. Basic training is usually sufficient for staff to operate them safely and efficiently.

- How often does a cardboard baler need maintenance?

Regular maintenance is crucial for optimal performance. Most manufacturers recommend a thorough check every 3-6 months, with daily and weekly basic checks.

- Can small businesses benefit from cardboard balers?

Absolutely! With compact models available, even small businesses can enjoy the benefits of cardboard baling. The key is to choose a baler that matches your waste volume and space constraints.

- How long does it typically take to produce a bale of cardboard?

The time it takes to produce a bale varies depending on the type and size of the baler, as well as the volume of cardboard being processed. For a typical vertical baler in a medium-sized business, it might take anywhere from 30 minutes to a few hours to create a full bale. Horizontal balers in high-volume operations can produce bales much more quickly, sometimes in as little as 10-15 minutes. The key is to choose a baler that matches your waste generation rate for optimal efficiency.

Cardboard balers represent a significant leap forward in waste management solutions. By understanding how these machines work and the benefits they offer, businesses can make informed decisions about incorporating them into their operations. From cost savings and improved efficiency to enhanced sustainability credentials, the advantages of cardboard balers are clear.

As the UK continues to push for higher recycling rates and lower carbon emissions, tools like cardboard balers will play an increasingly vital role in helping businesses meet these goals. By compressing waste, reducing transport needs, and facilitating recycling, these machines are not just an operational asset – they’re a step towards a more sustainable future.

Choose Landfill Alternatives today!

Landfill Alternatives offers a range of solutions to make your operations more efficient, cost-effective, and eco-friendly. Our unique Product Finder feature helps you identify the perfect baler for your needs, while our free on-site audit provides a comprehensive assessment of your waste management requirements.

Take the first step today: fill out our enquiry form, book a complimentary site survey, or request a callback from our expert team. We’ll guide you through our diverse range of cardboard balers and help you choose the ideal solution. Don’t let cardboard waste overwhelm your business – seize control with a tailored baling solution from Landfill Alternatives.