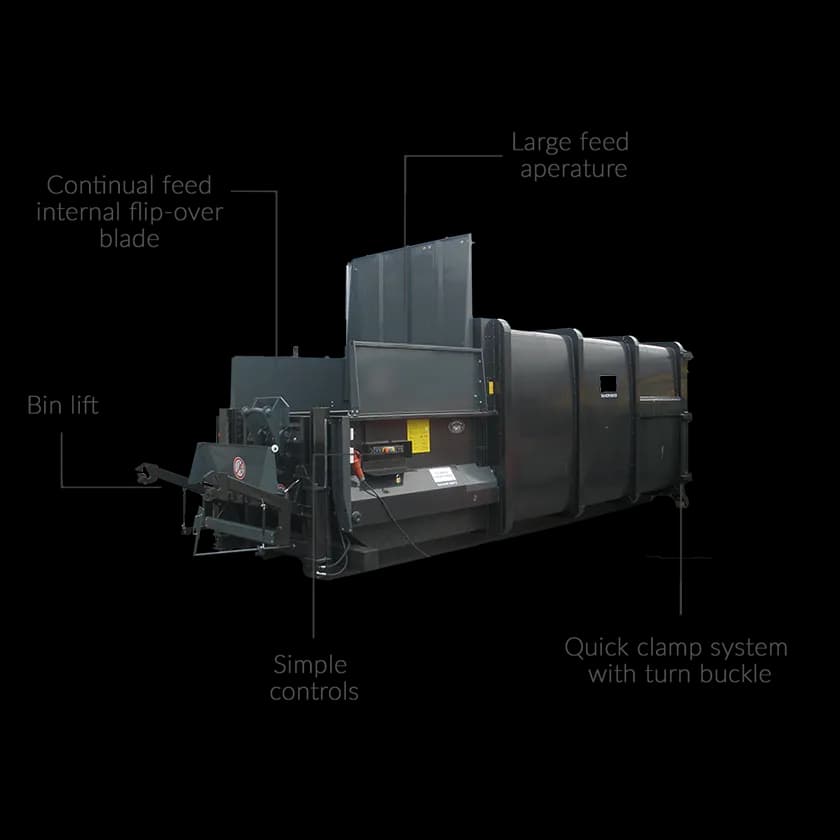

APB 20 BL

The APB 20 BL is our 20m³ dry waste portable compactor and one of the most popular machines in our range. Its purpose is to fully contain waste while reducing transport requirements, ensuring disposal charges are accurate and avoiding the costs of underfilled skips and bins. With a powerful 30-tonne compaction force, it achieves payloads of up to 8 tonnes of general waste — and in some cases up to 12 tonnes.

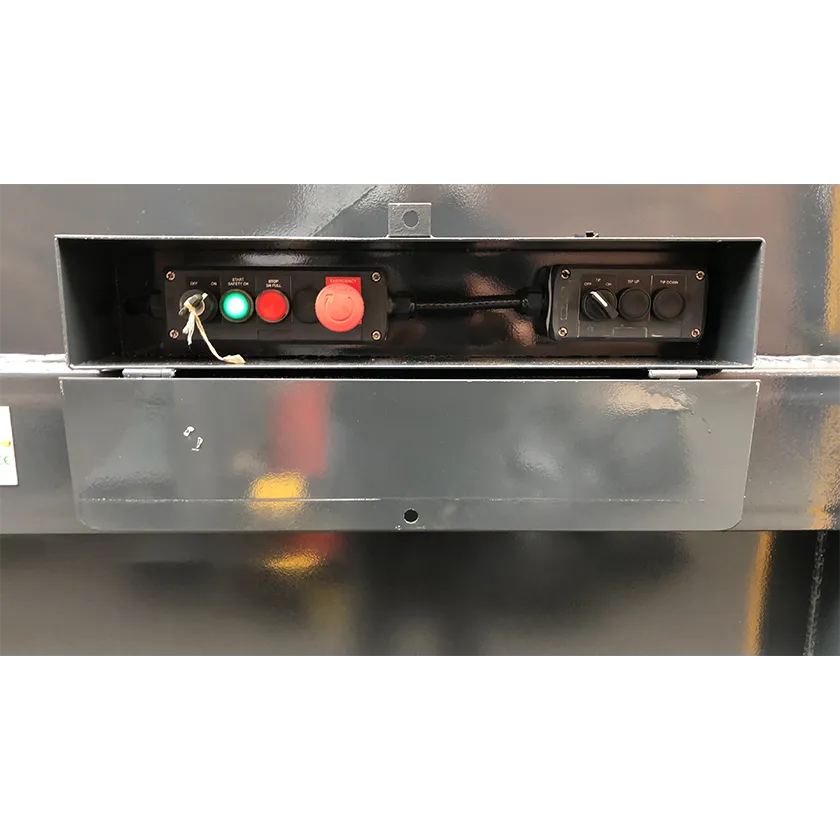

Featuring a large 1700 x 1800mm feed opening and a fast straight-push ram compaction system, the APB 20 BL is ideal for high volumes of waste. The ram is strong enough to break down bulky items such as pallets before compacting them into the sealed chamber, and the machine can be loaded in multiple ways including by hand, forklift, tipping skip, or tele-handler.

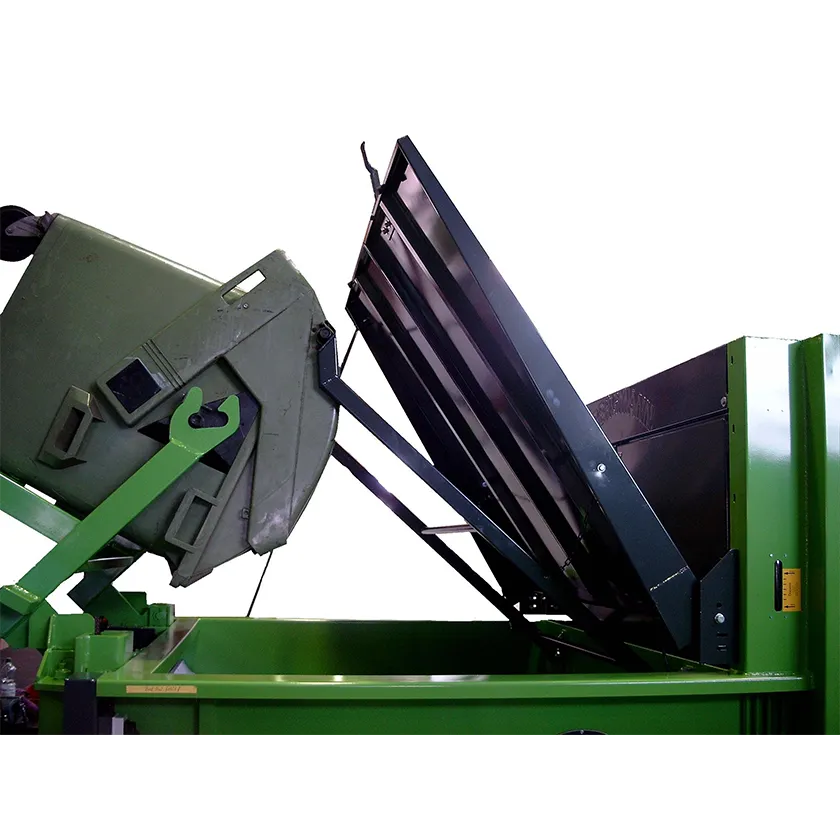

The integrated bin lift further enhances efficiency, reducing manual handling by allowing 1100L wheelie bins up to 450kg to be tipped directly into the compactor via its pintel system. For added safety, the bin lift can also be specified with a full safety cage.

Suitable For

General Waste

General Waste

Arrange a Callback with an Expert

We can help you pick the right machine to save your business money on waste disposal.

Compare with Similar Machines

This Machine | Smaller | |

|---|---|---|

| Price | From £75 P/W | From £64 P/W |

| Throughput | High | High |

| Suitable For |  General Waste General Waste |  General Waste General Waste |

| Machine Size |

|

|

| Feed Opening |

|

|

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.