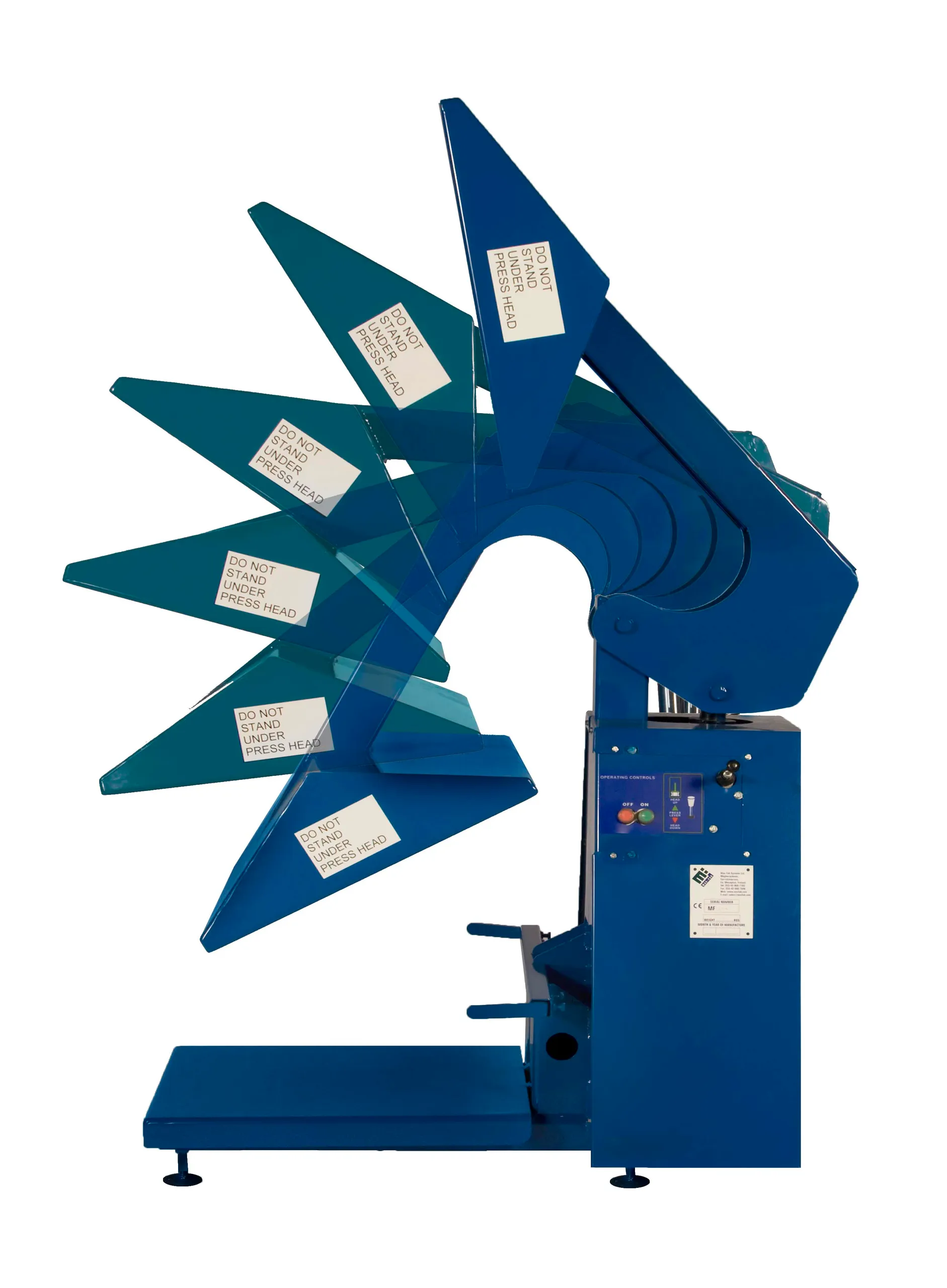

Refurbished Bergmann Roto Compactor

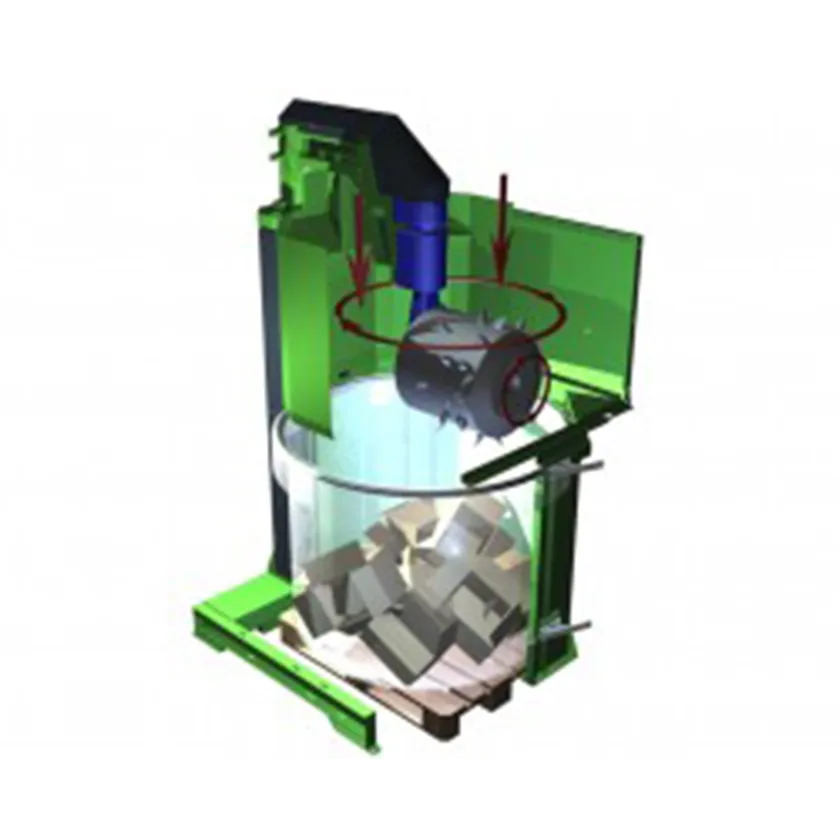

The Bergmann Roto Compactor is designed to compact waste directly into a heavy-duty bag using a rotating drum, positioned on a pallet. It is used on sites where waste needs to be compacted in a contained and controlled way before disposal, without the need for wheelie bins, skips or larger compaction equipment.

The Bergmann Roto Compactor is supplied by Landfill Alternatives as a refurbished unit. We keep these machines available, with each unit inspected and prepared prior to installation. This provides a lower cost option while avoiding the lead times typically associated with new equipment.

The compaction process uses a rotating drum that builds waste layer by layer inside a 1m³ heavy-duty plastic bag. This creates a dense block of material, with typical outputs of up to 700kg for general waste and up to 250kg for cardboard, depending on material type. Waste can be fed continuously through the drop-down feed door during normal operation.

The Roto Compactor is well suited to general waste, small cardboard boxes and packaging, and can also be used for polystyrene. It is commonly used as an alternative to cardboard baling where sites do not want to tie or handle bales. Once full, the bag is removed from the drum, sealed with tape and prepared for collection. The machine is not suitable for plastic film, as film can wrap around the rotating drum and cause damage.

Waste is compacted into a sealed bag held within a protective drum, helping keep waste contained on site and improving how waste is stored prior to collection. Once full, the bag can be removed from the machine using a pump truck. Filled bags are typically loaded using a forklift onto a curtain sider vehicle for disposal, or via a tail lift where a forklift is not available.

Due to its compact footprint, the refurbished Bergmann Roto Compactor (also referred to as a Rotary Compactor) is commonly installed where space is limited and larger waste compaction equipment is not suitable. Typical installations include offices, hotels, hospitals, bakeries, care environments, apartment buildings and other commercial premises handling general waste and cardboard.

The refurbished Bergmann Roto Compactor provides a practical way to reduce waste volume and manage general waste and cardboard effectively, without the complexity of balers or static compactors.

Available refurbished to purchase or lease.

Suitable For

General Waste

General Waste Paper

Paper Polystyrene

Polystyrene Cardboard

CardboardBale Weights

- Cardboard

- ~250kg

Arrange a Callback with an Expert

We can help you pick the right machine to save your business money on waste disposal.

Compare with Similar Machines

This Machine | Smaller | Larger | |

|---|---|---|---|

| Price | From £28 P/W | From £17 P/W | From £51 P/W |

| Throughput | Medium | Low | High |

| Suitable For |  General Waste General Waste Paper PaperDMR  Polystyrene Polystyrene Cardboard Cardboard |  Food Waste Food Waste General Waste General Waste |  General Waste General Waste Cardboard CardboardDMR |

| Bale Size |

| ||

| Machine Size |

|

|

|

| Feed Opening |

|

| |

| Bale Weight |

|

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.