Jumbo Roll Packer - Skip Compactor

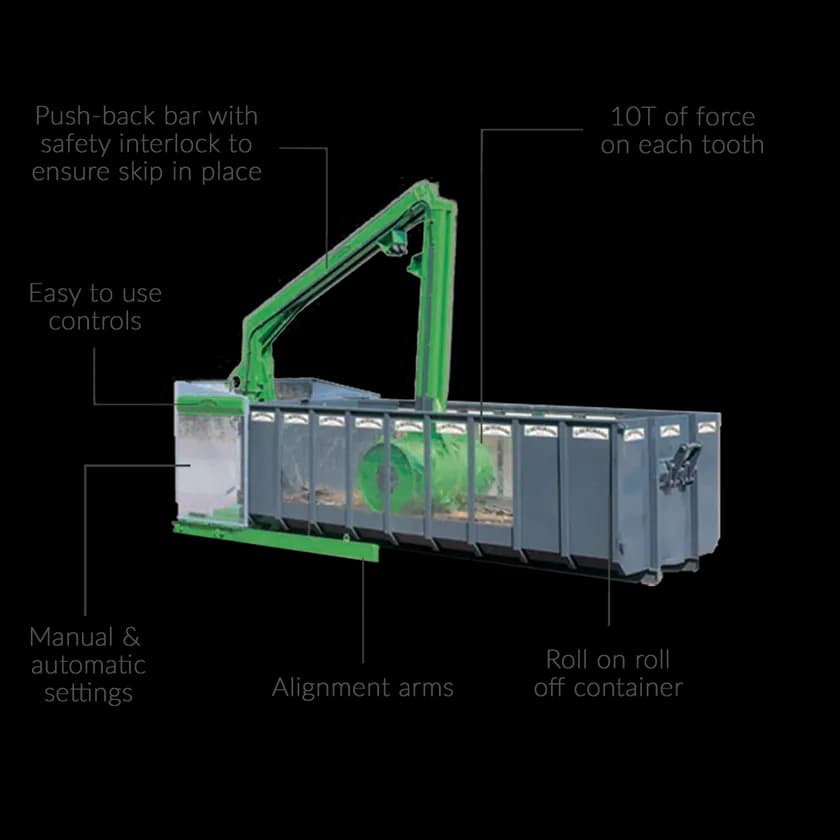

The Jumbo Roll Packer is one of the largest compactors in the Landfill Alternatives range and is primarily used for compacting bulky waste directly into 35 or 40 yard roll on roll off skips. The machine sits behind the RoRo skip and reaches over the top using a long arm and rotating drum.

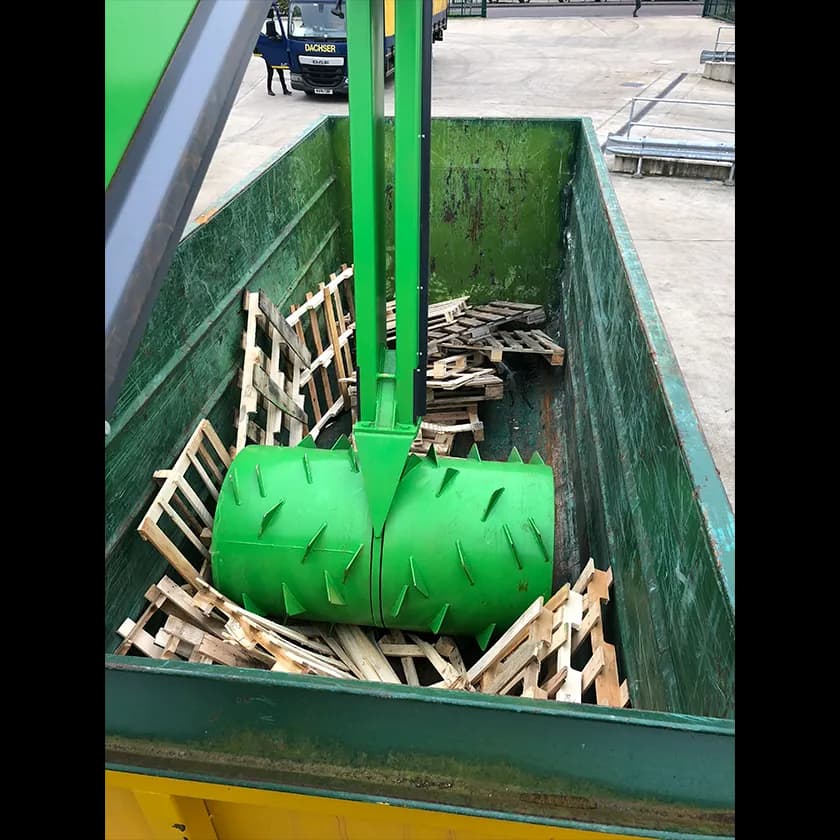

Compaction is achieved using an aggressive toothed drum that rolls backwards and forwards inside the skip, crushing and breaking down material into dense layers. This significantly reduces air voids within the skip, with compaction ratios of up to 5:1 achievable depending on material type. Where waste is stacked loosely, even higher compaction ratios can be achieved.

The Jumbo Roll Packer is most commonly specified as a wood skip compactor or timber waste compactor, particularly on sites producing large volumes of pallets, broken timber and bulky wood waste. It is especially effective where wood skips fill quickly by volume but remain well under weight limits, leading to unnecessary skip exchanges.

By compacting timber waste directly into the roll on roll off skip, the Jumbo Roll Packer allows more material to be loaded into each skip, reducing how often skips need to be changed saving transport costs. While primarily used for wood waste, it can also handle other bulky materials such as general waste, cardboard and mixed bulky waste where standard compactors are not suitable.

Waste can be loaded into the skip as it is produced, with the roll packer run as required during the day. When a skip is full, it can be changed without moving the machine, keeping disruption on site to a minimum.

The Jumbo Roll Packer is used on UK sites such as timber yards, recycling yards, manufacturing sites, distribution centres and waste transfer facilities. It can be installed inside or outside and is designed for heavy, day-to-day use.

Available new or refurbished to purchase or lease.

Suitable For

Wood

Wood Pallets / Other Large Objects

Pallets / Other Large Objects Flexible Metals

Flexible Metals General Waste

General Waste Metal / Plastic Cans

Metal / Plastic Cans Rigid Plastic

Rigid Plastic

Arrange a Callback with an Expert

We can help you pick the right machine to save your business money on waste disposal.

Compare with Similar Machines

This Machine | Smaller | |

|---|---|---|

| Price | From £96 P/W | From £61 P/W |

| Throughput | High | High |

| Suitable For |  Wood Wood Pallets / Other Large Objects Pallets / Other Large Objects Flexible Metals Flexible Metals General Waste General Waste Metal / Plastic Cans Metal / Plastic Cans Rigid Plastic Rigid Plastic |  General Waste General Waste Cardboard CardboardDMR |

| Machine Size |

|

|

| Feed Opening |

|

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.