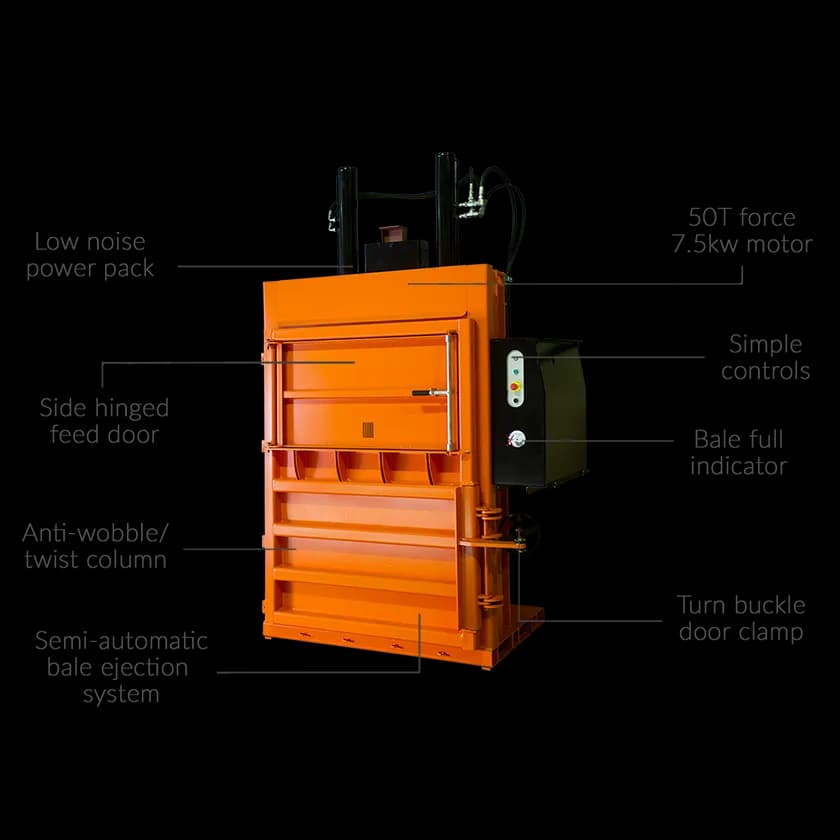

LFA 500

The LFA 500 is a large vertical mill size baler used throughout the UK for many years, trusted and recognised by recyclers and has been a core part of our range for over 20 years. Built for heavy duty use, it produces wire tied mill size bales weighing up to 520kg (depending on material). With a large 1185 x 610mm feed opening, 55 second cycle time and 50 tonnes compaction force, it’s designed to handle high volumes of commercial and industrial recyclable material with ease.

To gain the best rebate on your recyclable material, recyclers require mill size bales, which the LFA 500 produces. Featuring an automatic bale ejection system, it makes removing bales quick and simple. Its IP65 rating means it can be sited indoors or outdoors, withstanding all weather conditions.

Common recyclables baled include cardboard, plastic film, rigid plastics and paper, though it is capable of compacting a wide range of materials. We have supplied the LFA 500 to many different industries including manufacturing, food production, logistics, recycling, retail, construction and public sector organisations.

Suitable For

Cardboard

Cardboard Fabric

Fabric Flexible Metals

Flexible Metals Flexible Plastic

Flexible Plastic Paper

Paper Rigid Plastic

Rigid PlasticBale Weights

- Cardboard

- ~500kg

- Plastic

- ~520kg

Arrange a Callback with an Expert

We can help you pick the right machine to save your business money on waste disposal.

Compare with Similar Machines

This Machine | Smaller | Larger | |

|---|---|---|---|

| Price | From £39 P/W | From £24 P/W | From £39 P/W |

| Throughput | High | Medium | High |

| Suitable For |  Cardboard Cardboard Fabric Fabric Flexible Metals Flexible Metals Flexible Plastic Flexible Plastic Paper Paper Rigid Plastic Rigid Plastic |  Cardboard Cardboard Fabric Fabric Flexible Metals Flexible Metals Flexible Plastic Flexible Plastic Paper Paper |  Cardboard Cardboard Fabric Fabric Flexible Metals Flexible Metals Flexible Plastic Flexible Plastic Paper Paper Rigid Plastic Rigid Plastic |

| Bale Size |

|

|

|

| Machine Size |

|

|

|

| Feed Opening |

|

|

|

| Bale Weight |

|

|

|

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.