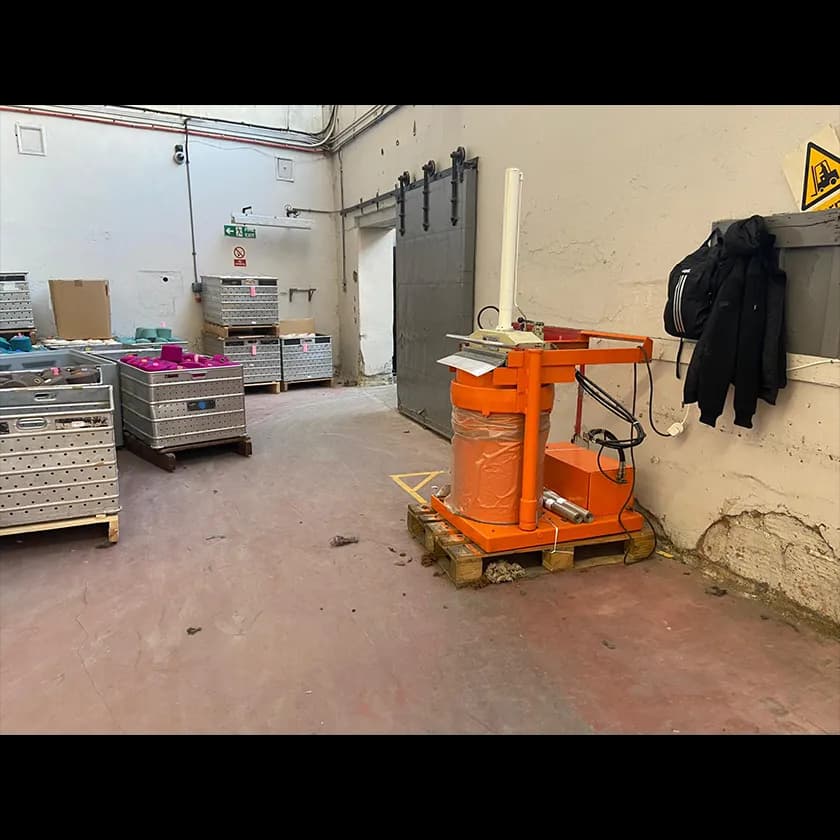

LFA BP - Bag Press

The LFA BP is a small bag press designed to compact bagged waste into a drum before disposal. It uses 3 tonnes of compaction force, applied over a small surface area, allowing a large quantity of bagged waste to be compacted into a much smaller volume, achieving reductions of up to 10:1.

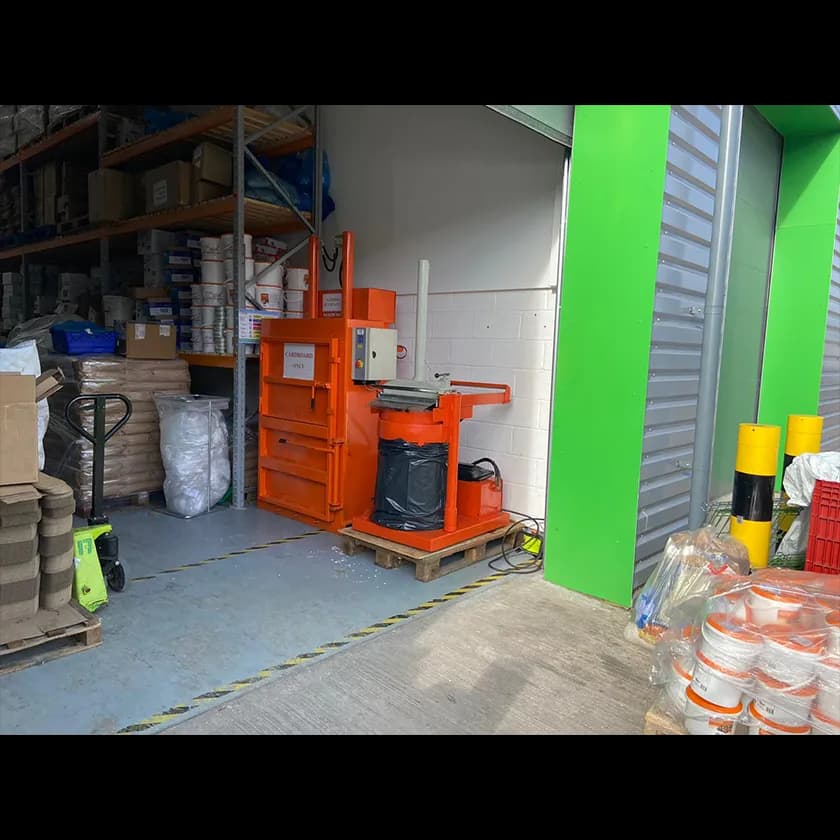

Because the machine has a compact footprint, the LFA BP is commonly installed where space is limited. It is regularly used in UK offices, hotels, kitchens, hospitals and other commercial environments where waste is produced in bags rather than handled loose in bins or skips.

The LFA BP can be used with both wet and dry waste and is straightforward to operate. Waste is loaded into the top of the machine and compacted using simple button controls.

When a bag is full, it is removed from the drum and placed into a wheelie bin or skip for collection. This type of bin bag compactor supports waste volume reduction, meaning less space is required for stored waste and collections are reduced.

The LFA BP provides a solution for businesses looking to manage bagged waste more efficiently where space is restricted and larger waste compaction equipment is not suitable.

Available new and refurbished to lease or purchase.

Arrange Free Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.